Striping

Internal Warehouse Striping Services

ASG Services lead the way in floor marking technology, with concrete preparation, floor coating materials and application methods.

Providing striping solutions throughout the US.

Warehouse Striping.

Industrial line marking is a dual-purpose product used in logistics and distribution centers around the world.

Internal floor marking is used to improve storage efficiency by clearly designating areas.

It is used for safety in demarcation for pedestrian access routes, forklift truck aisles and no-go-zones, all critical guides to separation without complete restriction.

ASG Services are a leading provider with benchmarking quality standards, provided to customers throughout the US.

Experience

Our Track Record.

ASG Services have led the way in marking technology for many years, through concrete preparation, floor coating materials and application methods. In all this, durability and a cost-effective approach have been fundamental factors.

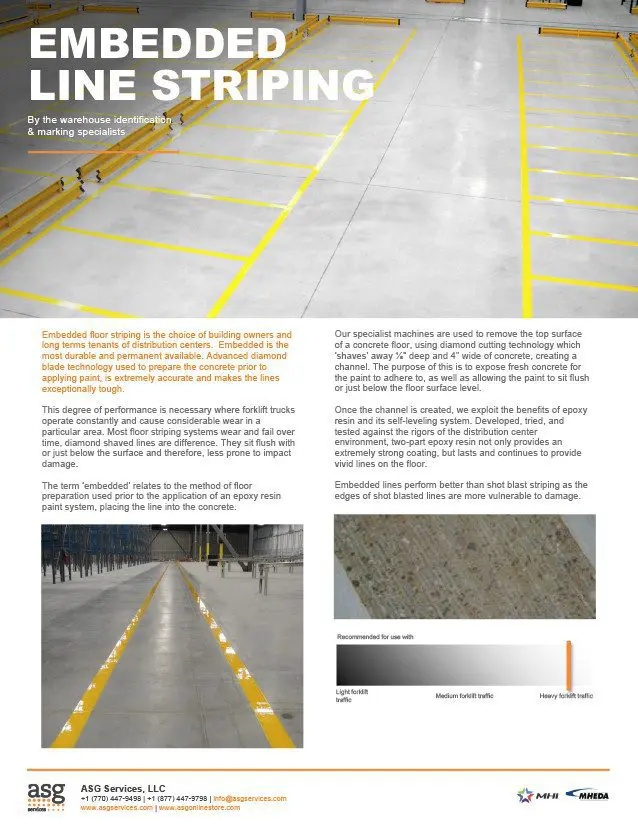

Concrete preparation is central to achieving durability. Customers can have mechanical preparation carried out by shot blasting, grinding or shaving.

These methods remove the smooth and/or old surface of a concrete floor to varying degrees, which in turn create alternate levels of performance. It can be likened to preparing wood before treatment. The fresher and rougher the surface, the longer the coating will last.

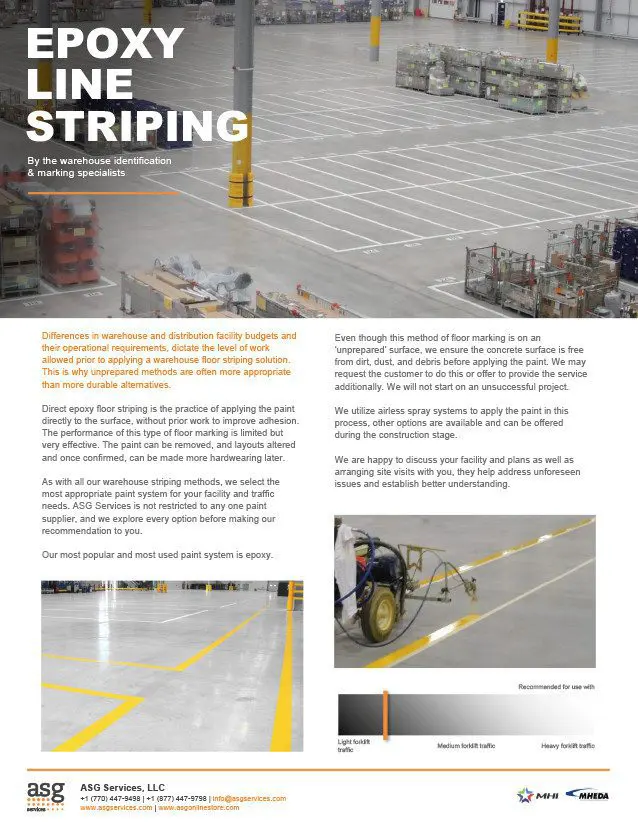

Some customers are unable to prepare their floor surfaces due to contractual restrictions. Fortunately, ASG Services have sourced several floor-marking products which perform well without preparation.

Although limited, we are confident that with the correct pre-work, these options will impress. We utilize all types of paint formulas and chemical mixes to ensure every floor type, usage and state restriction is addressed.

Typical types include solvent free epoxy, solvent based epoxy, acrylic, polyurethane, polyaspartic and chlorinated rubber.

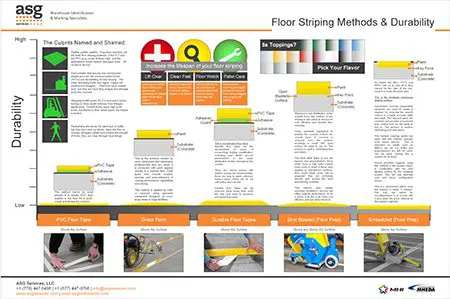

Methods Provided by ASG Services.

We offer the best solutions to meet the customers needs, not those that suit our business. The methods we adopt are:

Paint methods:

- Direct applied epoxy – paint applied without preparation (can be removed later),

- Shot blasted – the most cost effective and durable method,

- Durable embedded – the most durable form of internal marking available,

Floor tape methods:

- Floor tape – economy grade floor tape for temporary and none traffic use,

- Durable tape – also available from our online store (www.asgonlinestore.com).

All methods and materials come in a range of colors making them ideal for 5s integration.

The benefit of multiple preparation options for the customer is that we can customize the variations per area of your facility. Using the more durable options in the busiest areas and cheaper options in low traffic areas, means your budget goes further and floor marking performance is maximized where needed.

A Professional Installation Team is Essential.

ASG Services floor marking projects are among the largest carried out in the world. The vast scale and quantity require the most professional and organized approach possible, which is why we present every project in stages. This allows us to establish a schedule for the customer to use in pre-planning for our installation progress.

If the project is particularly complex and requires it, a project manager will visit the site prior to the installation to help with planning and preparation. This is a great opportunity for the customer to understand how multifaceted these projects can be. Read more about our line marking drawings.

Our installation personnel are trained and insured to carry out aisle marking installation works on all customer sites.

Resources & Takeaways

Downloads

Looking for adhesive floor tape? Search our online store for reliable, high-quality products, crafted with technology for trusted durability.

Our Client List Keeps Growing!

Help & Advice

Frequently Asked Questions

What preparation is best for my warehouse?

Preparation helps improve durability, so if you are operating a very busy facility or moving items which are heavy, you will likely need a preparation method.

There are several options to consider:

- Heavy traffic areas – consider embedded striping,

- High traffic – consider shot blasted,

- General and low level-traffic – it may be possible to use an epoxy directly on a cleaned surface. However, this has a low durability rating as with tape.

It is typically more cost effective to have a preparation method when compared to several years of recoating and touch-ups which will be needed.

What colors should I use?

OSHA recommends the following:

- Yellow. – Yellow shall be the basic color for designating caution and for marking physical hazards such as: Striking against, stumbling, falling, tripping, and “caught in between.”

- “DANGER” – Red, or predominantly red, with lettering or symbols in a contrasting color.

- “CAUTION” – Yellow, or predominantly yellow, with lettering or symbols in a contrasting color.

- “WARNING” – Orange, or predominantly orange, with lettering or symbols in a contrasting color.

- “BIOLOGICAL HAZARD” – Fluorescent orange or orange-red, or predominantly so, with lettering or symbols in a contrasting color.

Most work carried out by ASG Services is done with yellow and/or white. Occasionally we will be asked to use red, green, blue and grey. If in doubt ask what we can provide, almost any color is available.

What floor marking dimensions are typical in warehouses?

The most common dimensions are in walkway widths (4ft), pallet lane widths (pallet type dependent plus the line width) and line widths (4”), but every facility is different and may need custom sizes.

OSHA provides the following:

“The lines used to delineate the aisles may be any color so long as they clearly define the area considered as aisle space. The lines may be composed of dots, square, strip or continuous, but they too must define the aisle area.

The recommended width of aisle markings varies from 2 inches to 6 inches; therefore, any width 2 inches or more is considered acceptable.

The recommended width of aisles is at least 3 feet wider than the largest equipment to be utilized, or a minimum of 4 feet.”

Standard Number: 1910.22(b) – Compliance with Aisle Markings (Part 1910.22(b)) – [Corrected April 17, 2009] – Read Compliance with Aisle Markings.

Why should I consider integrated markings?

Combining your storage markings with passageways or safety markings can help save money over time. This comes from shared demarcation boundaries and downtime during installations, plus reduced mobilization, plant hire and material costs.

Will I need to give you a drawing? How detailed should it be?

For the most accurate price and planning, it is best to give us as much as possible, having a drawing helps you visualize and us to plan and quote. CAD are easiest as we can use them to pull measurements from, while PDF with measurements added is another great way to provide us with the information.

However, this is not essential, we can help with basic depictions or arrange for a partner firm to visit site and create a much more detailed drawing, contact us for pricing.

How can I look after the lines once I have them?

Keeping the area clean and clear of debris is the easiest thing any facility can work on. However, we strongly recommend customer work on their training programs to encourage the following:

‘Clean Care’ – The cleaner the floor is, the less abrasive items there are to wear the lines, maintain a cleaning regime to suit your operation.

‘Lift Clear’ – Ensure the forklift truck drivers and warehouse operatives lift pallets clear off the floor before maneuvering.

‘Turn Clear’ – Only turn the MHE steering when the wheels are clear of the lines. Twisting on the line will wear the paint surface and pull it off the concrete in some cases.

‘Clean Feet’ – Entrance mats can reduce the amount of dirt and debris carried in on shoes.

‘Floor Watch’ – Instill awareness in the workforce to remove debris and harmful objects when they are spotted.

‘Pallet Care’ – Removing or repairing damaged pallets will prevent them being dragged and gouging the coating.

When should I consider re-coating work?

You will find that recoating is only needed where lines are driven over or turned on. Floor markings along the length of bulk storage lanes for example, typically remain as good as when they were installed.

Striping applied directly to the floor in busy areas may need a recoat within the first month or two in heavy traffic areas or more typically the first year of use. Shot blast prepared lines should reach 3 to 5 years and diamond shaved around 5 to 6 years.

These are estimates and very based on facility use, traffic levels and floor conditions.

How long will it take to install?

Our project teams can forecast, with a good level of accuracy, installation times of all products we produce and the floor markings we create.

Many factors come into the calculation as you might expect, such as quantities, dimensions, etc, so a detailed discussion will be needed to develop the time frame. We use this framework for all our project planning as we know our speedy completion is often the last in the larger process.

Why should I consider the more expensive option?

The simple and short answer is durability. Durable line striping is more expensive because there is a lot more work involved in preparation and the machinery needed.

Preparation is critical for paint to adhere well to most surfaces and unfortunately, concrete is a very hard material which takes time to work and prepare. The positive consideration is that more durability means less re-working later, so the investment pays off.

I want to change parts of the layout, what will I need to do?

During an installation, our team on site can relay any updates or requests to the project team, or support you with ideas and possibilities. They are experienced with this situation and will work with you to achieve the preferred outcome. Our project and sales team will work remotely on re-planning, pricing and scheduling to maintain professional control.

After installation, again just let us know. We can remove, cover up and install most products during installation, and schedule for a return visit for amendments or additions.

Our safety team has found problems with slip hazards, what can you do for us?

We have several options including mating, adhesive anti-slip products bolt down anti-slip plates as well as anti-slip paint coatings. All are designed for specific uses and varying durability but ultimately, consideration must be given to the use of an area where injury is a risk.

You can find some of the standard products on our anti slip floor tape page.

Do line widths matter?

Line widths are not critical, but there are several considerations to make, some are as follows:

- OSHA considers lines of 2 inches and greater to be acceptable to provide floor markings for aisles and passageways.

- Narrow lines become more difficult to see inside buildings.

- Four-inch-wide lines are standard through the logistics and distribution industry.

- Narrow lines wear out quicker as there is less paint on the floor.

- Very wide lines may need an anti-slip aggregate finish applied where moisture is present.

Other considerations:

- A more visible marking on the floor draws more attention and so heightens safety.

- The layout measurements must include line widths to ensure a pallet fits within the markings. Pallets on markings can damage the line.

- A narrow line needs less material so cheaper.

Case Studies

We’ve helped hundreds of companies

Case studies from some of our customers who are improving their warehouses.

Find more…

Contact us and discover how we can help.