Yes, we can retrieve information from our archive and apply this to your new location references, effectively replicating your previous warehouse identification system.

What we do

Project Services

Being a supplier to many of the world’s largest companies is something we at ASG Services are proud of and yet something we never take for granted.

Expert professional warehouse identification & marking services.

Our project services range from advising customers in the initial stages of a label, sign or striping project, to providing fully managed installation services of advanced warehouse identification and marking systems. All are developed for the logistics and distribution industry.

In preparation for an installation of rack labels, barcode signs, line striping, etc., we have added levels of support services, including product design, location data handling, floor layout drawings and 5s visual concepts.

We aim to help and enable customer success through high quality products and professional services.

Advice, design, creation, data development, and installations,

Our Services

-

Sign Installations

Selecting the right warehouse signs requires particular attention to detail. Technical specifications in materials, production methods and installation, all have an effect on overall performance.

-

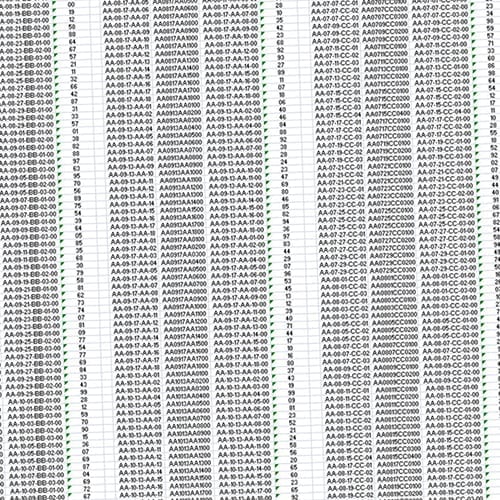

Storage Location Data

Why not email with your questions and any data information for us to consider with the response?

-

Warehouse Floor Striping

ASG Services provide several methods of warehouse floor striping, each with their own characteristics and prices.

-

Warehouse Label Designs

ASG Services are a leading manufacturer specializing in customized designs to suit each customer’s individual need.

-

Warehouse Labeling

Our experience in warehouse labeling and installations allows us to draw on years of expertise through product design to label layouts on the racks.

-

Warehouse Sign Designs

ASG Services’ production team are able to create every variation or warehouse sign needed, as well as matching previous designs.

Warehouse Label, Sign & Striping Installation Services.

ASG Services’ installation teams travel throughout the US applying durable barcode labels, hanging thousands of barcodes signs, and laying miles of line striping every year.

Teams are fully trained and insured, with the vital experience needed for swift and accurate work.

Attention to detail and understanding of distribution center environments helps them work in and around issues with ease. Their pace and focus is unquestionable helping ASG Services meet customer expectations.

Our Client List Keeps Growing!

Reading

Related Articles.

-

Naming Warehouse Storage Locations

Today’s dynamic logistics centers are not just shelves full of boxes, they are meticulously designed environments. They handle goods of unimaginable variations and are refined for…

-

Why use a Warehouse Labeling Specialist?

Warehouse labeling projects are better when a specialist is used. They are critically important when planning a warehouse labeling job.

-

Workplace Shadow Boards and Plant Productivity

Looking at how 5S workplace shadow boards and plant productivity improvements are impacting logistics and distribution centers.

-

What is a 2D Barcode?

Two-dimensional scanners were once far more expensive than linear readers, but recent developments and data needs have made the cost of 2D worth the investment,…

-

Strategic Move on the Road to Excellence

Keith Morley, owner of ASG Services said, “Atlanta is a great location for us, it has been ideal from the start for transport, suppliers and…

-

OSHA Guidance For Floor Marking Consistency

While it is a simple OSHA requirement that the “permanent aisles and passageways shall be appropriately marked”, it is very vague when it comes to…

-

The Benefits of Safety Barriers and Floor Striping

Overview Protection In Areas Of Danger. The decision to use either is not difficult, how to use them is key. ASG Services project teams work…

-

Branded Warehouse Signs Add the Professional Touch

Warehouse signs, the functional, simple and often forgotten essential of the storage and distribution industry, have just been brought to the fore with a ‘brand’…

Help & Advice

Frequently Asked Questions

-

You did our facility in OH and we have another opening in PA, can we get the same type of signs for that site?

-

Would we have to grind the concrete a little bit for your tape to stick?

If the floor is a regular smooth concrete surface and clean, you will not need to grind.

A thorough clean is recommended, and a solvent clean would be advisable if you suspect any contamination. Once the floor is dry, it should be good to go.

If the floor is rough, then you would need to make it smooth. Either by grinding, or coating with a screed.

Mighty Line floor tape is very strong, so with scrapers and elbow grease, you will be able to remove it in one piece. There may be residual adhesive left in places, and a simple adhesive removal spray would take care of that.

-

Will I need to give you a drawing? How detailed should it be?

For the most accurate price and planning, it is best to give us as much as possible, having a drawing helps you visualize and us to plan and quote. CAD are easiest as we can use them to pull measurements from, while PDF with measurements added is another great way to provide us with the information.

However this is not essential, we can help with basic depictions or arrange for a partner firm to visit site and create a much more detailed drawing, contact us for pricing.

-

Why use color?

It is true that location labels do not need color to work, but we recommend color to help the users identify key location information quicker. Color is know to improve speed of identification, to read more visit our warehouse color coding article.

Color identification may be used as a level indicator on racking where each level in a rack bay has a unique color, so as the operative looks up, they can distinguish the level quickly and shorten their reading time. It can also be used as a zone identifier particularly with bulk storage floor locations, aisle groups in racking and shelving is another.

Another well represented use of color is with warehouse striping for staging lanes, bulk storage bays and walkways. See our warehouse striping page for more information.

Some customers use it for aesthetics for their in-house branding.

Find more…

Contact us and discover how we can help.