Labels

Pallet Rack Location Labels

ASG Services are specialist custom manufacturers of rack location labels. We produce them for all types of companies with a common need for storing pallets on racking. Our specialist approach provides durable products with high-definition print for the best performance and capability in industrial environments.

Designed, produced and installed throughout the US.

Pallet Rack Location Labels.

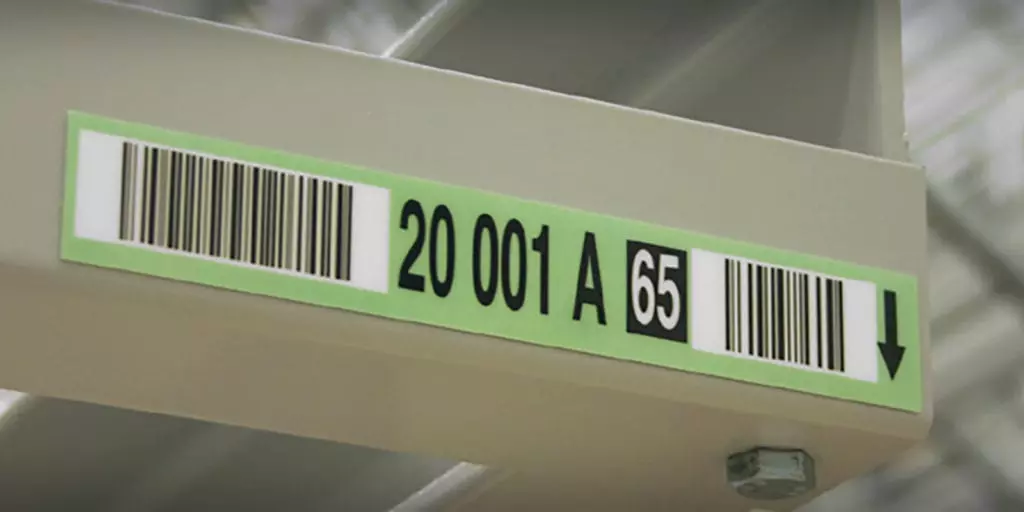

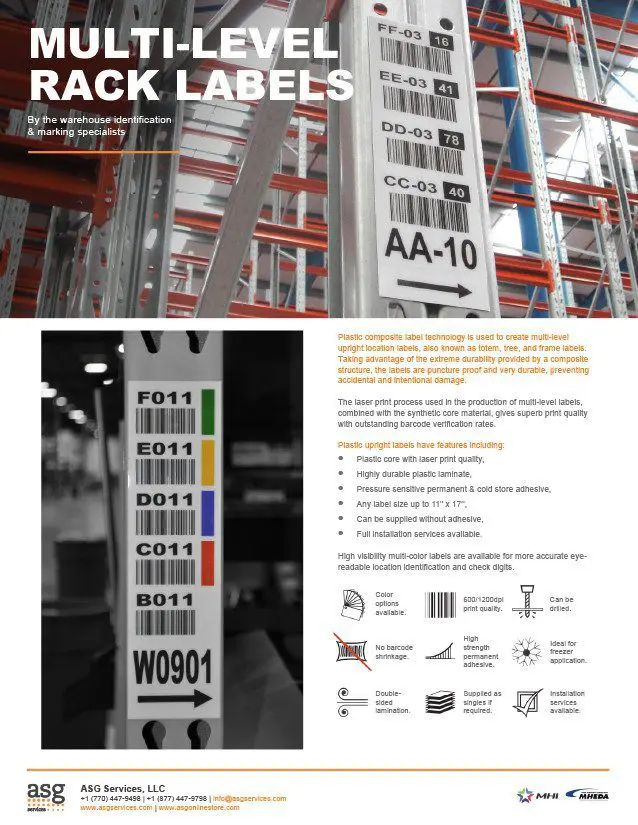

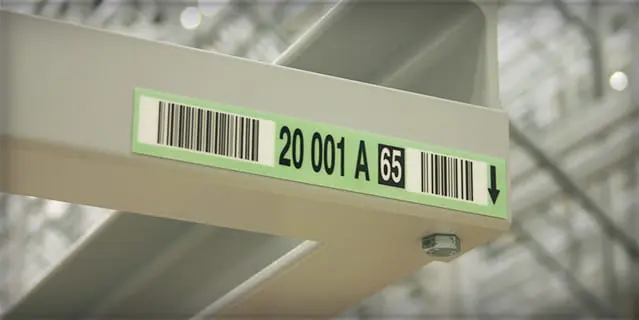

Each barcode location label leaving ASG is different from another, the design, content, colors, material and more, combine to make a unique label for a unique pallet location in your facility. At ASG Services, we design and produce mono and full color layouts. Color rack location labels are used to help differentiate racking levels, storage zones and in some cases, product groups.

We work closely with customers to establish the best design and content to suit their needs. Often customers will have a predetermined design, others can draw from our experience and design archive, for a custom design.

Read more about our storage location data management.

Specialist software is developed to handle mass variable data in multi field designs, making it possible for us to print high-definition barcodes, alpha, numeric and alphanumeric content with ease.

We utilize the latest print technology to create our rack labels. At ASG we believe a high performing barcode is critical to meeting the demands of the fast-moving industry they are used in. Barcode scanners have vastly improved in the past 10 years and will now scan most barcode qualities. However, not all facilities have the latest technology and performance. Regardless of technology, we uphold our policies on quality and performance and produce the very best pallet location labels possible.

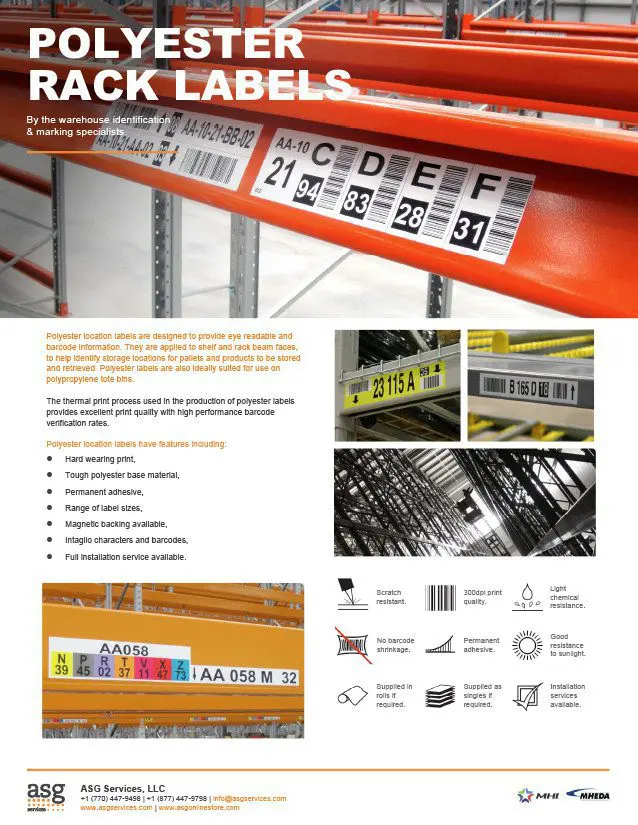

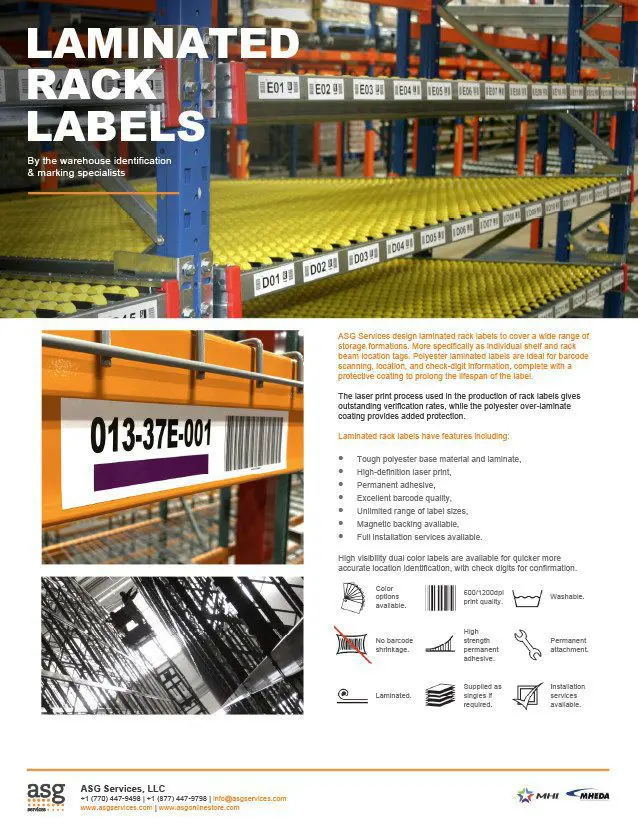

Advanced materials in label production are important for industrial use, ASG’s polyester rack labels are among the toughest available thanks to the characteristics of polyester. We find they can withstand more impacts than any other base material. In addition, we also apply a protective coating to help shield and protect the print as well as making a slightly thicker and tougher tag. The laminate coating is also high-grade polyester.

Key Performance Benefits of Our Materials.

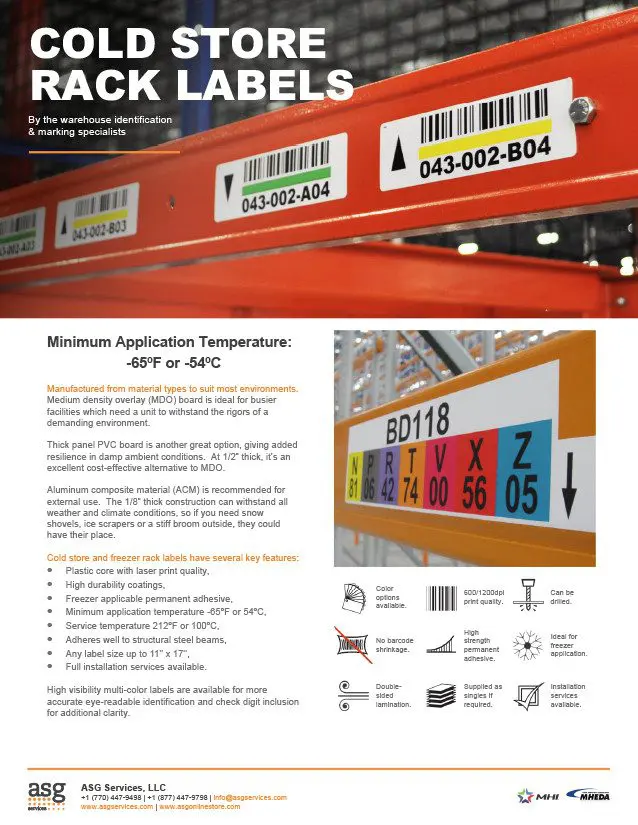

Plastic Composite – A formation of several layers to create a rigid label which integrates the print for protection, is much harder wearing and combined with specialist adhesives, idea for cold and harsh environments.

Polyester – An extremely strong and stable material retaining original profile, therefore print clarity and deflection is beyond almost any other, which is perfect for barcode labels.

3M Retro Reflective – Returns a far greater amount of light to the source allowing barcode readers to detect bars from much greater distances, therefore labels can be placed on high beams beyond the normal scannable distance.

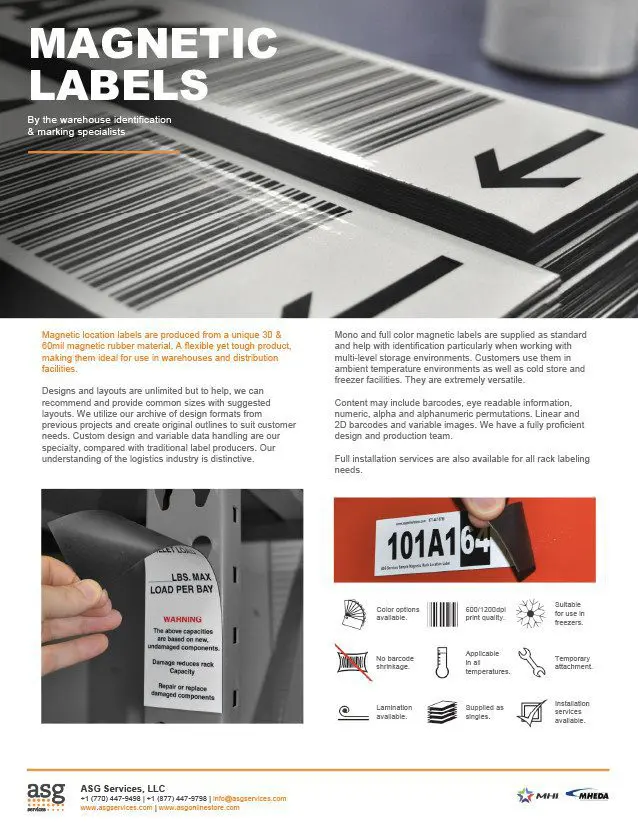

Our variations can be applied to most materials such as metals, rigid rubber, plastic, smooth wood and concrete. Backings include clear, magnetic and self-adhesive with some thicker adhesives used for rough surfaces.

Most rack labels can be produced as singles or on rolls. The way they are presented is entirely up to the customer, some prefer to have all labels on a roll which can prevent them being mishandled, others prefer singles as it is often easier to install them.

Removable and Repositionable Label Adhesive.

The adhesive used on our Restick rack labels is developed to act like a standard permanent adhesive. It has a strong initial tack level and can remain in place long term.

The difference is, Restick adhesive can be removed and replaced without molecule separation, meaning the adhesive remains on the label, with none left on the beam surface.

The adhesive maintains its characteristics so the rack or shelf labels can be repositioned and reapplied multiple times.

Services

Project Managed Installation Services.

ASG Services is renowned for its installation project management services.

We provide professional, fully managed and insured installation teams throughout the USA, who install location identification products daily. Their attention to detail and understanding of warehouse location number sequences is essential in achieving the volume and accuracy they are capable of.

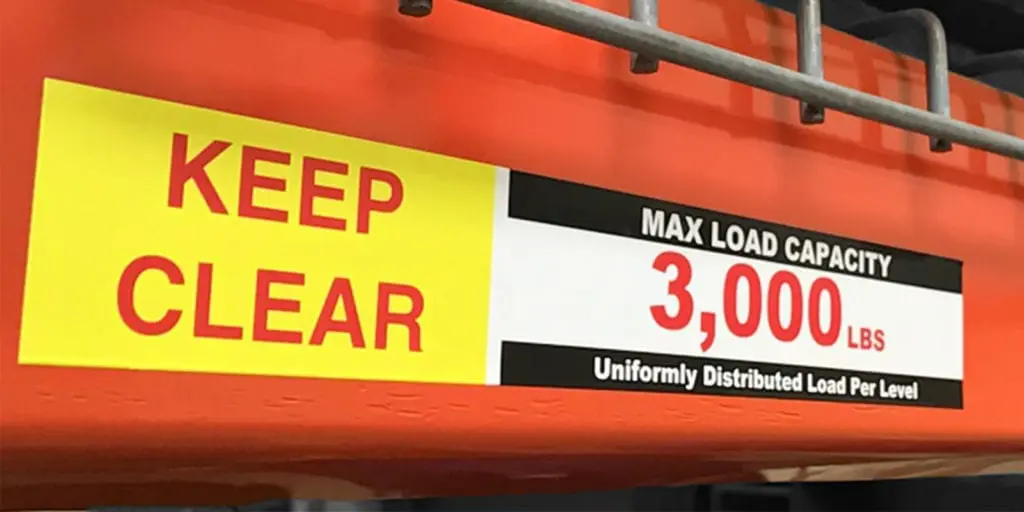

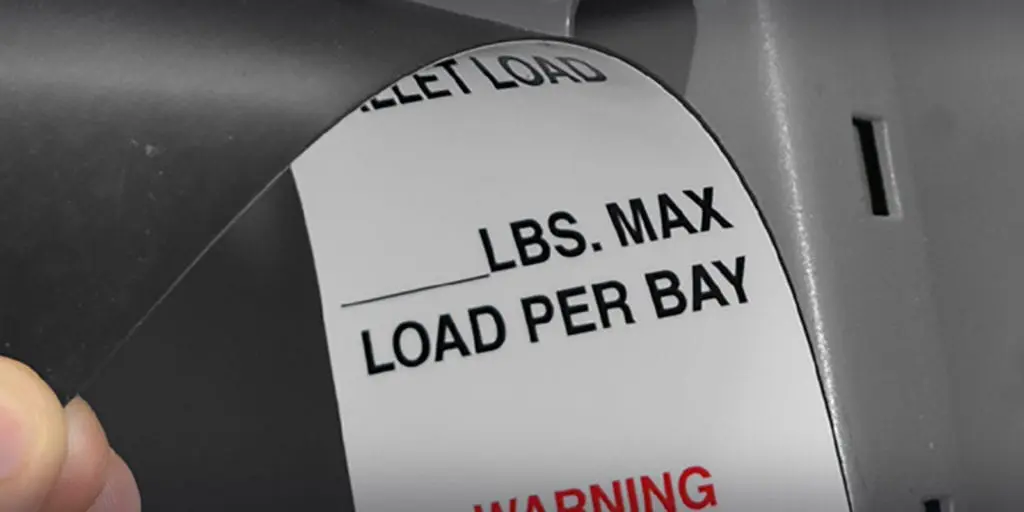

All types of warehouse location labels are installed, including those designed for cold store, multi-level, magnetic, weight capacity, reflective and flue space indication.

We invite you to contact us and start your project discussions early. The more information we can share the better, such as considerations regarding your racking layout, location numbering convention and any operational restrictions.

The detail matters for accuracy.

Pallet Rack Label Data.

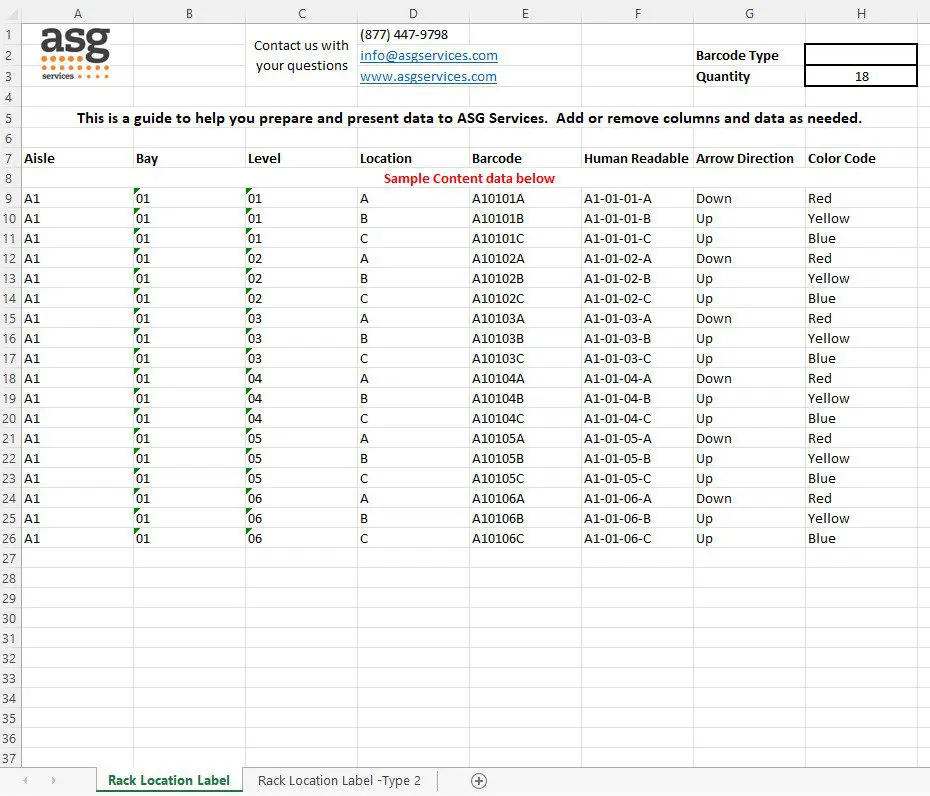

Our customers provide label data in various forms, from the very simple to the often very complex. To help improve accuracy and order processing time, we have given examples of how data can best be prepared by customers, before sending it to us.

We understand the limitations and complexities involved, so please speak to us about your data if you need help, it’s one of the things we are good at.

Below, you will see the layout example to help with the build and presentation of rack label data. We have suggested the following headings, to help with your data gathering and our data manipulation prior to production. They are:

Have you built your location data file yet?

Download a blank rack label data file here.

An Excel document to help create your own.

Aisle: The aisle reference could be single or multi digit, we used A1, as the first aisle in the row.

Bay: The bay relates to the space between the rack frame legs, where beams stretch across to create shelves.

Level: The level number, or letter (Number in our example), relates to the storage level. This could be the floor, or the first beam. We have shown 6 levels here, but yours may be less or greater.

Location: Within each bay, the slot or location position across the beam, may be 1 to 2, or 3 where pallets are stored, or 01 to 12 or more if small parts are stored on shelves.

Barcode: The barcode content is usually made up of all location references combined, in a continuous string, some customers use separation symbols, but we have shown the most common continuous method.

Human Readable: This information is generally the same as the barcode information, a combination of the location data. However, customers often add symbols and spaces to make the information easier to read by warehouse operatives.

Arrow Direction: Where arrows are required, adding a simple Up, Down, Left or Right is adequate. We have shown Up and Down as these are to be used on the beams.

Color Code: A significant benefit to location identification is in adding a color to denote levels. A simple word reference is best here and where a particular color reference is required, these should be listed separately. Red, (#E04116) for example, added to a separate cell at the top of the page, works best. A printed color match cannot be guaranteed.

Barcode Type: Enter the barcode symbology you require, this could be one of many types, so if you are not sure, please ask your system provider, or we can recommend the most common linear or 2D used in the industry.

Quantity: If the formula is updated to cover the full list you create, the quantity of labels will be shown which you can cross reference with other location count information. It helps you ensure all is included and shows us what is needed immediately.

Tabs: At the bottom of the page, we have shown a main and a ‘Type 2’ tab. You may name it differently to related to the location type, label size, project reference, etc. Having separate tabs helps us see which data is for which label and helps you check all needed are included.

Ask Us.

Please feel free to speak to us about your data, it is very much in our interest to ensure your data is good to go and that we can process the order swiftly, so we are more than happy to help. You can find contact details here.

Answering Your Questions

Rack Label Types.

If this is your first warehouse labeling project, it’s likely you are unfamiliar with the terminology, usage, positioning, materials and design possibilities. We understand your situation and frankly, it’s why we are here, to help you. Visit our Rack Label Types page to discover more about the stickers that help make distribution centers work.

We are committed to supplying solutions which perform to the highest standards possible, while ensuring it is cost effective.

Types covered:

- Base,

- Split Base,

- Multi-Level Beam,

- Upper-Level Beam,

- Level Indicators &

- Upright Location.

Resources & Takeaways

Downloads

Our Client List Keeps Growing!

Help & Advice

Frequently Asked Questions

What sizes do you offer?

Any size you need. Every order we fulfill is customized, so you can specify the size, and we will provide the product as needed.

What designs can you create?

We are not a graphic design studio, but we can design any label layout required. Variable content data and multi field options are possible, our only restriction on the number of barcodes and characters is the size of label you request. We will always suggest a size which best suits your requirements.

Is color more expensive?

Yes, simply because the raw materials we need to create color labels are more expensive, however once an order is over a certain size, the extra cost becomes negligible.

Why use color?

It is true that location labels do not need color to work, but we recommend color to help the users identify key location information quicker. Color is known to improve speed of identification, to read more visit our warehouse color coding article.

Color identification may be used as a level indicator on racking where each level in a rack bay has a unique color, so as the operative looks up, they can distinguish the level quickly and shorten their reading time. It can also be used as a zone identifier particularly with bulk storage floor locations, aisle groups in racking and shelving are another.

Another well represented use of color is with warehouse striping for staging lanes, bulk storage bays and walkways. See our warehouse striping page for more information.

Some customers use it for aesthetics for their in-house branding.

Can I have check digits?

Yes, these are common requests from our customers looking for pick accuracy improvements.

Which barcode is best?

The barcode you choose to use is dependent on your location or product reference data requirements.

Although we can produce almost any barcode type you require, Code 128 is by far the most requested by the storage and logistics industry. This is in part due to the range of characters which can be used (128), being all digits, characters and punctuation and because of its data to size percentage, lots of data can be stored in this narrow width barcode.

Code 39 is the next most popular, which is less useful in terms of characters it can encode, but it is great for its simplicity and ease of scanning capabilities. This is often used with operations handling product specific references and a need to work quickly.

More recently we have been asked for Data Matrix and QR Codes which can contain huge amounts of data compared to linear barcodes.

I have a design already, can you copy it?

Yes, if we have a sample or measurements and a good image we can copy your label almost exactly.

If you install the labels, what assurances can I expect?

- Every label will be in the correct place.

- Labels applied to the rack or shelf in a consistent manor for a uniform presentation.

- If you have missed information from your location references, our team will report back to ensure they are made and on site before the facility goes live and hopefully applied before we leave site.

- Barcode and content accuracy.

- Barcode performance and verification guaranteed as an additional service.

Case Studies

We’ve helped hundreds of companies

Case studies from some of our customers who are improving their warehouses.

Find more…

Contact us and discover how we can help.