Unprepared floor striping is a term given to epoxy paint which is applied to the floor without any concrete preparation taking place.

Often, customers are restricted and not able to prepare the concrete floor. ASG Services have developed methods and preparation techniques which do not affect the floor surface.

Warehouse floors should be cleaned thoroughly and free from dirt, dust and residue before anything is applied. ASG Services inspect each floor before installation and if needed will recommend further cleaning.

If our installation teams feel they are able to address any concerns whilst on site, they would sweep areas or use a thinners based solvent.

Customers are expected to carry out the main cleaning process prior to ASG Services arrival and start of the installation of epoxy floor striping.

However, ASG Services are experienced in the use of floor cleaners and often perform this task as an additional service. Customers are asked to discuss this with their technical sales associate during consultations.

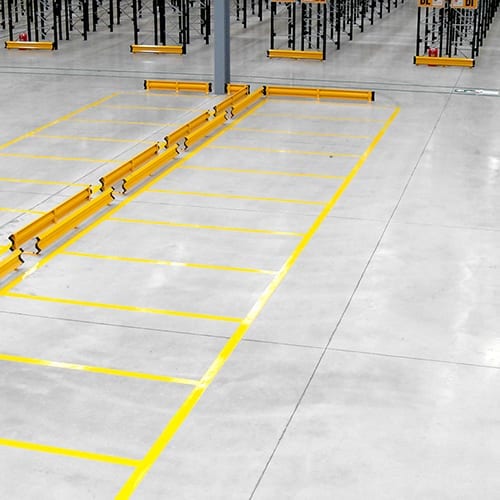

Once the area is prepared, the installation teams will use either a controlled spray application method or roller to apply paint directly to the concrete surface. Our teams often use a combination of marking methods to achieve highly accurate markings which are always based on customer specifications.

Durability of the epoxy paint method is good. Although our preparation techniques for this method are thorough, they are not comparable to shot blasted or embedded floor marking.

Painted floor marking can be expected to last longer than floor tapes, including the durable floor tape range available on our online store. Paint adheres to concrete as well if not better than adhesives, but is not as thick so is less susceptible to damage by impact.

Additional work can be provided to help with the lifespan of your epoxy striping, visit our Clear-Coat Floor Marking page for more information.

Our project management teams work closely with customers to understand their operational and space requirements during the installation.

We understand it is essential for ASG Services to progress swiftly, while not disrupting the customer’s operation. The project teams also ensure where progress surpasses expectations, the customer is informed to make early decisions.

All projects are planned with site drawings and depictions of floor marking layouts, giving customers a preview of the markings to come.

ASG Services employs fully trained and insured installation teams who carryout warehouse epoxy floor marking installations on a daily basis.

Their attention to detail, knowledge of materials and equipment is second to none, not to mention their appreciation for the customer’s needs.

ASG Services are specialist manufactures of warehouse signs and labels and while working with customers on line striping installations, often provide the bulk storage signs and installation services to complete a full service.

Visit our warehouse hanging sign page, or call us on (877) 447-9798 to discuss your needs further.

The simple and short answer is durability. Durable line striping is more expensive because there is a lot more work involved in preparation and the machinery needed.

Preparation is critical for paint to adhere well to most surfaces and unfortunately, concrete is a very hard material which takes time to work and prepare. The positive consideration is that more durability means less re-working later, so the investment pays off.

Combining your storage markings with passageways or safety markings can help save money over time. This comes from shared demarcation boundaries and downtime during installations, plus reduced mobilization, plant hire and material costs.

For the most accurate price and planning, it is best to give us as much as possible, having a drawing helps you visualize and us to plan and quote. CAD are easiest as we can use them to pull measurements from, while PDF with measurements added is another great way to provide us with the information.

However this is not essential, we can help with basic depictions or arrange for a partner firm to visit site and create a much more detailed drawing, contact us for pricing.

OSHA recommends the following:

Most work carried out by ASG Services is done with yellow and/or white. Occasionally we will be asked to use red, green, blue and grey. If in doubt ask what we can provide, almost any color is available.

Feel free to contact us and ask the questions that matter to you, we're happy to help and to become part of the solution.

If you need information for a project you are working on, drop us an email with questions, images, drawings and anything else which might help us suggest a program or solution that suits you.

Shot Blast Floor Striping

Shot Blast Floor Striping

The preparation method used, of removing the concrete surface using a shot blast machine, combined with an epoxy resin compound or similar applied, is the most cost effective high performing solution available.

Durable Striping

Durable Striping

The premium warehouse striping solution is ASG Services world renowned embedded striping.

Our online store provides customers with the opportunity to purchase standardized products. The same technology, production and quality control methods are used, so you can be assured of their performance and durability.

Browse now