Signs

Sign Installations

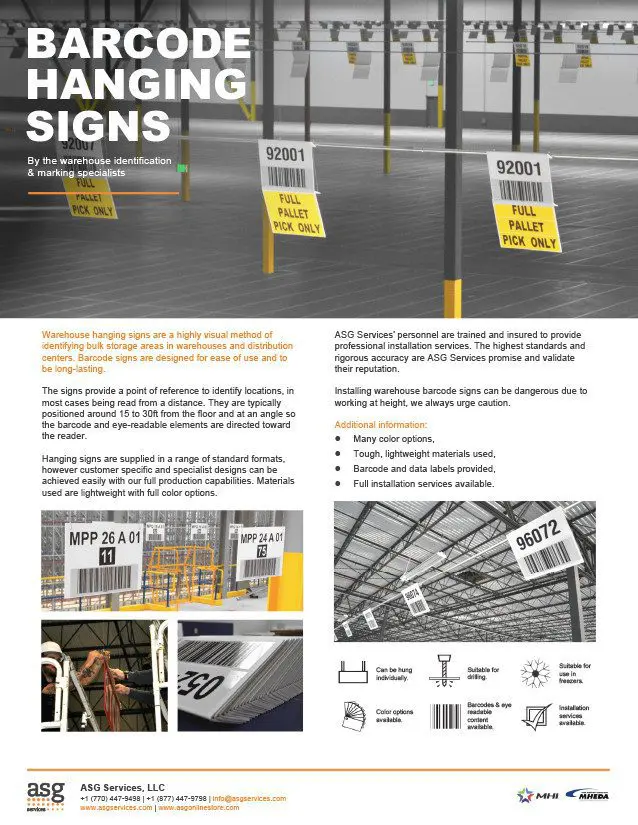

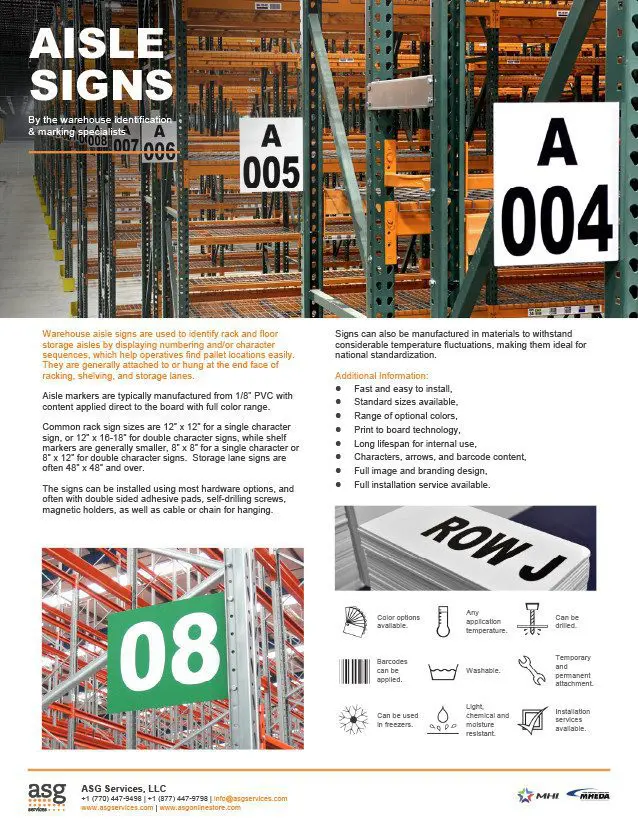

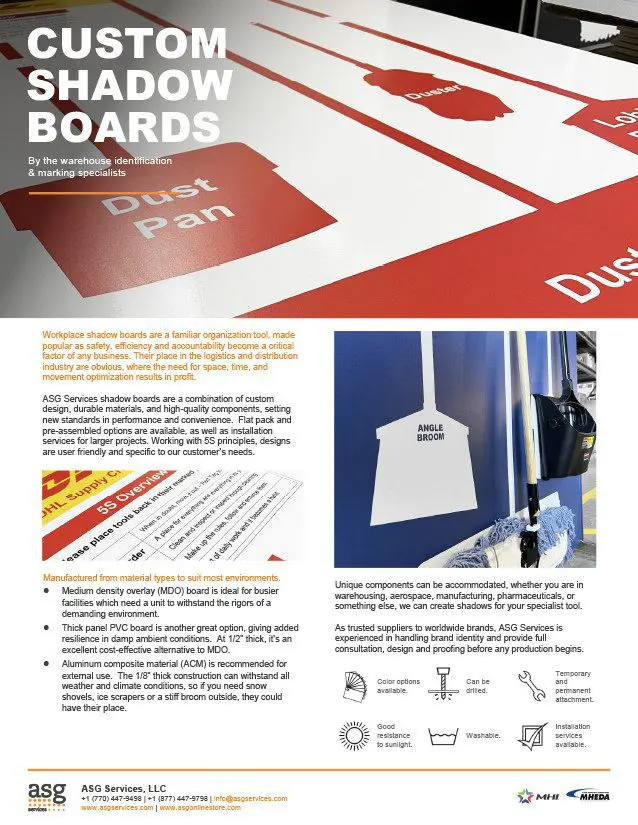

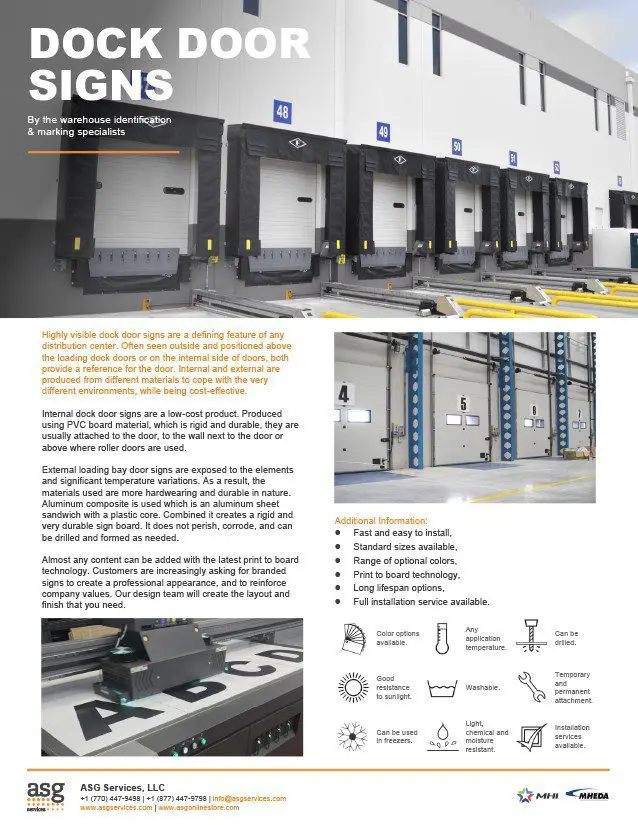

Selecting the right warehouse signs requires particular attention to detail. Technical specifications in materials, production methods and installation, all have an effect on overall performance.

Providing managed installations throughout the US

ASG Services are the leading warehouse sign installers, providing professional services from consultation, design, planning and implementation of projects. A typical project is hard to determine since our installation teams might install 5 to 15,000 depending on the facility needs.

Our approach has become the benchmark for others which we consistently work to improve on, removing the load and bringing confidence in a successful project. Our simplified process is as follows:

Initial Consultations.

Selecting the right warehouse signs requires particular attention to detail. Technical specifications in materials, production methods and installation all influence overall performance.

Location signs are often single-sided, in some cases the customer can utilize both faces and even request multi face signs. The more complex the design, the more consideration is required, which is why ASG Services are best placed to offer advice. Our experience and previous designs are a resource for customers to take advantage of.

Different considerations are required for safety and utility signs, messages, images and visibility at distance are key to their effectiveness, we help guide customers on size, color and message options.

Once we have discussed the type, design and usage of the sign, we would then move to the installation and project delivery considerations. Storage location signs are installed with high-grade hardware. We will pick the most appropriate and cost effective for your project.

Design and Planning.

The intrusive nature of sign installations means they require consideration for both parties. The overwhelming reason is safety. Bulk storage signs are most often installed from suspended hardware. Therefore, the installation equipment and location are often susceptible to materials handling equipment (MHE) traffic.

Our project management teams will work closely with the customer to agree access and schedule requirements for both to work effectively.

Following the initial consultation phase, ASG Services’ production team create drawings, samples and prototypes of the finished sign were required. The customer can then agree and confirm their design with a tangible item, which is of particular benefit when the item is new to their facility or operation. Other proofing techniques are used ordinarily, and once agreed, all is set to go.

Almost every sign-based product to leave ASG Services is different from another, so you can be confident that your identification and barcode signs will always be custom made to your requirements.

Once all is confirmed and ready, your ASG Services project team will move into full preparation for the imminent installation. They will (unless customer preference dictates) arrange access equipment, installation materials, personnel and a lead installation manager to attend site throughout. During a sign installation, frequent reports are sent back to our head office to update on progress and any anomalies which occur that need further investigation.

Our customers can expect to receive a completed project with minimal disruption and maximum cost effectiveness.

Services

Warehouse Sign Installation Management.

The importance of storage space being made available is always a priority consideration for ASG Services. Managed sign installations are always subject to this and can often affect more than 72 pallet locations per sign, so installation planning and accurate coordination is critical.

During the initial consultation and proposal stage, the customer and ASG Services will have worked together to find the best fit schedule for the operation and ASG’s capabilities. This forms the installation program in such a way to govern, while maintaining flexibility should an irregularity arises.

Installation managers will report their progress to ASG Services project teams who will make continual checks and measurements, ensuring the installation is on track and advising of any impending issues or delays.

All installation team leaders are fully trained and insured to carry out sign installations and to work on all customer sites, existing and new-build facilities. They are fully aware of the dangers and considerations required when working on new build sites as well as the access restrictions and dangers in existing facilities.

Customers are always consulted before, during and after an installation to ensure they are comfortable with the plan, current events and that they are happy with the result.

You can read more here, about some of our warehouse sign installation projects.

Experts Do It Better.

Professional Warehouse Identification Installations.

Resources & Takeaways

Downloads

Our Client List Keeps Growing!

Help & Advice

Frequently Asked Questions

Where do your installation services cover?

Most of our installation projects are based in the US, but we also travel throughout the world with customers who know and trust in our services. We also partner with similar suppliers around the world, so we can often refer you to a company closer to you if needed.

Are your guys trained and insured to work in my building?

In short, yes. Our teams are trained in-house and with the relevant external training centers to ensure they know how to do their job and how to do it safely. Any employee who we feel is endangering the safety of others is dealt with swiftly.

Do you carry out installations in new buildings?

Yes, in small and large buildings. We are very experienced in working around other contractors on new builds and carefully plan with the customer and main contractors to achieve a completed installation.

Do you carry out sign installations in existing facilities?

Yes, this is a specialty of ASG Services. Working in and around a fully operational distribution center can be daunting, not to mention having a significant impact on productivity. Our teams are very experienced in how to work within these facilities and appreciate that the customers’ work ultimately comes first.

How much room do you need when installing?

Depending on the scale and access requirements we may be able to work without affecting your operation, or we may need to provide detailed work plans which show how much we can do, where and when. The project team will also detail access requirements and safe working areas to be agreed and confirmed with the customer.

How high should I hang my new signs?

There are several things to consider with the height of signs, they are:

- Sprinkler interference – Signs should always be placed at sufficient distance from sprinkler heads to ensure the diffusion is not altered or prevented by the signs or rails. If you hang the signs above, this is not an issue.

- Block stack storage height – The signs will need to be higher than the highest stacking point, but you should consider here that if the signs are hanging behind the front edge of the stack, they will need to be higher still, due to the angle of sight.

- Scanner distance capabilities – Most modern scanners are equipped with long range scanning components. However, this should be checked with the manufacture/supplier. If you want to test the distance before ordering, you might consider requesting a sample to perform on site tests.

- Sign/barcode size – In a simple explanation, the wider a barcode is, the greater the distance it can be scanned at. Having a wider barcode will need a bigger sign, resulting in a more expensive product.

Case Studies

We’ve helped hundreds of companies

Case studies from some of our customers who are improving their warehouses.

Shop now for reliable, high-quality products crafted with standardized designs with technology for trusted durability.

Find more…

Contact us and discover how we can help.