Labels

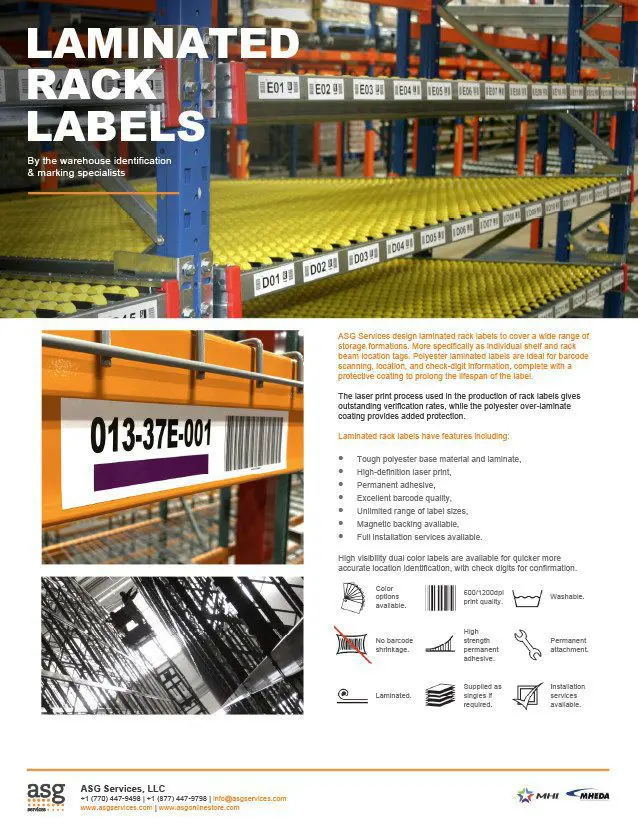

Wire Deck Rack Labels

ASG Services have developed new wire deck rack label layouts to maintain performance and make their application a little easier.

Designed and produced in-house, installed throughout the US.

Waterfall Wire Deck Labels.

The need for wire or mesh decks on pallet racking has changed the way rack labels are designed and used. For years, they were individual labels identifying individual locations and later came the multiple location layouts, however with the wire deck in place, the usable face of rack beam edges have reduced and so ASG Services have developed new wire deck rack label layouts to maintain performance and make their application a little easier.

Designing barcode labels for warehouse racking is a process of applying necessary content in a layout which is intuitive on all levels of use. Squeezing content is the most straightforward option when space is restricted, but in some cases, it makes the content so cramped that the label becomes more difficult to use. Therefore, we need to be a little smarter with wire deck rack labels, we design, test, re-design and test again until we have a layout that offers clear identification that fits within the limits of the rack face and most importantly, which the customer is happy to implement.

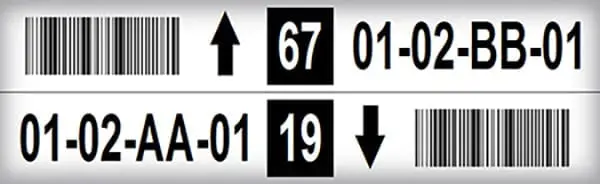

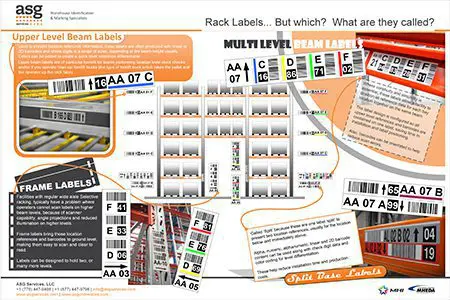

Typical Horizontal Rack Label Designs.

Single Location.

- The least effected design of the three, this can be increased or reduced in size without losing any significant performance.

Split Base Location.

- Designed to identify the floor and first level locations, saving cost for the customer in materials and installation time. One label application instead of two, literally halves the amount of time and cost spent installing them. They also help reduce confusion as their layout design makes it very clear which level they represent.

Multi-Level Location.

- A design made popular in operations where higher levels need to be scanned from the ground, this one label can identify locations from the ground upwards and so in a 6-high bay, where 5 or 6 labels would previously have been applied to the rack face, now one can be added, reducing cost and installation time massively.

Differences

How the old and new designs compare.

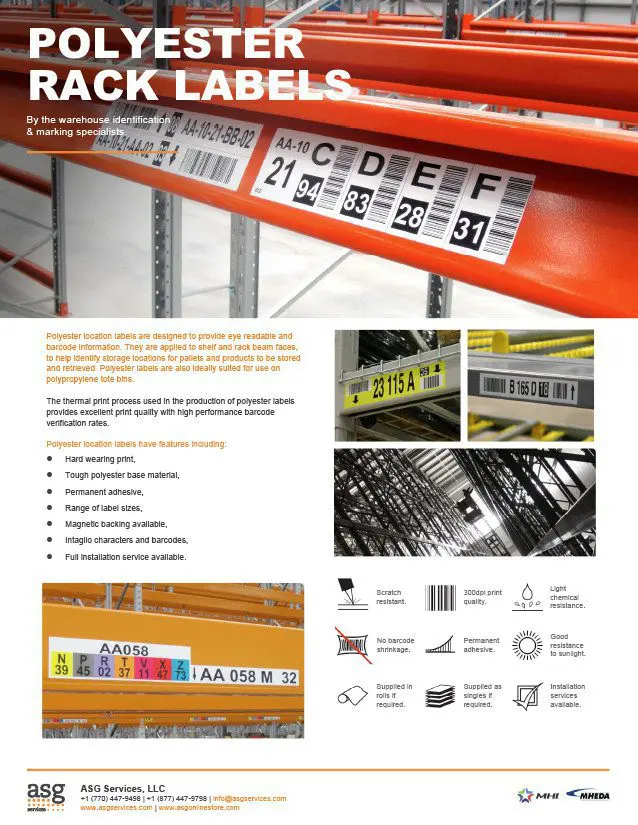

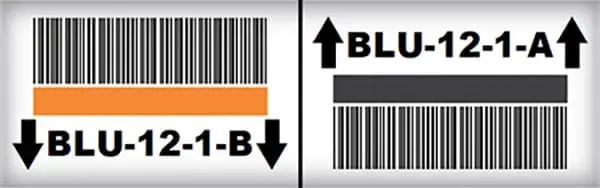

Typical Split-Base Design.

In this design, the ground level location reference is on the lower half of the label and the first level on the top half. This makes it easy quick to read location names, to understand which barcode to scan and the direction of location order on the rack face.

Wire Deck Split-Base Design.

The content remains but the layout face has been reduced in height to 2.5″ which allows for the length to also be reduced and the overall cost of the label lowers. The content has been laterally spread, maintaining scan performance and reference separation. This label can now be applied to the rack face with wire decks in place and will be as long lasting as the rack.

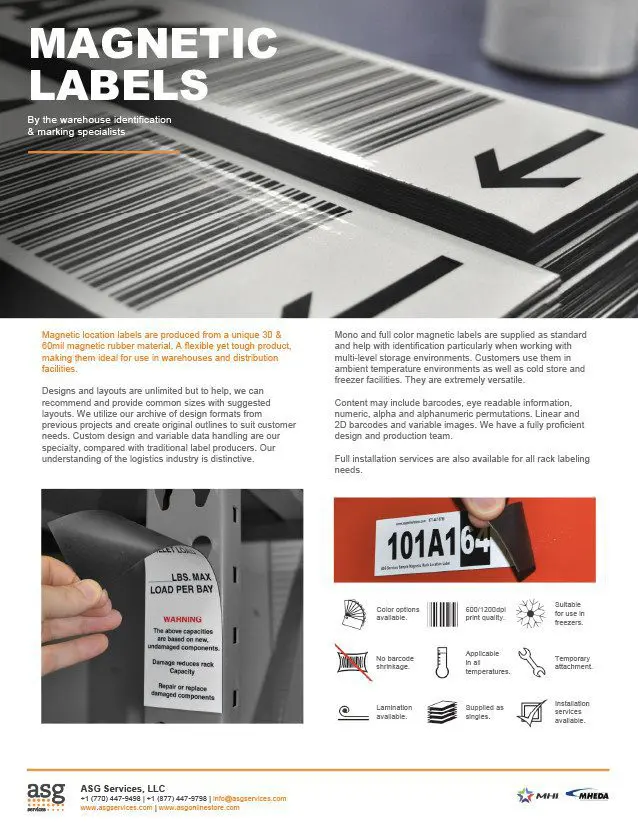

Typical Multi-Level Design.

Each location is listed in order from left (lowest) to right (highest) and are clearly identified by the color separation and arrow detail. The label length is determined by the number of levels in a rack face, but our designers carefully limit space used which maintains cost effectiveness, put simply, the bigger the label, the more it costs the customer, so we’re careful not to be wasteful.

Wire Deck Multi-Level Design.

This variation benefits from the horizontal layout of a typical design, however a simple crush of content would not be the simple answer as the aspect would make it difficult to read and to some extent make it unusable as an effective point of reference. The designer has incorporated the floor and first level in this layout which helps save on installation costs as one label is used where 4 might have been previously.

Snap Shot

Rack Label Infographic.

Services

Professional Rack Label Installations.

Installing wire deck rack labels require a little more care due to the wire deck edges and limited space to apply the label. It is important that a polyester label is always placed on the flat surface and never around the rolled corner. Doing so encourages the label to peel away which can then be snagged and pulled off. Regardless of this characteristic, polyester remains the most suitable material due to its durable nature and stability, eradicating label stretch and retraction which can affect scan performance.

ASG Services installation team’s carryout rack label installs daily, making them experienced enough to prevent delays and undue obstructions. They are accurate in their label positioning on the beam and detailed enough to get the right label in the right location. The real and tangible benefit of their expertise is in their speed. Projects are completed sooner, and customers can be operational much faster than if they used their own teams.

As a specialist in the field, ASG Services have provided millions of warehouse barcode labels throughout the world and thousands of rack label installations, so be assured that when it’s time to contact us, you will be speaking to the most capable, experienced and customer centric experts in the industry. Feel free to call and discuss your wire deck rack label needs and remember, the designs we have demonstrated are examples and can be altered in any way you prefer, custom warehouse labels are our thing.

Contact ASG Services on (877) 447-9798 or email info@asgservices.com to start your relationship with them.

Resources & Takeaways

Downloads

Our Client List Keeps Growing!

Find more…

Contact us and discover how we can help.