Labels

Long-Range Retro Reflective Pallet Rack Labels

The intensity of the returned light to the scanner means it can travel further, enabling the operator to be further away from the pallet rack barcode label.

Designed, produced and installed throughout the US.

Retro Reflective Labels.

ASG Services produce all types of warehouse labels with unique barcodes, location references, arrow images and any other variable data content, all to meet individual customer needs.

Retro reflective rack labels bring specific benefit offering barcodes that scan at 20ft away with ease.

Our production techniques utilize the latest technologies needed to produce high-definition print imagery which improve scanning verification and process speed.

What is retro-reflective material?

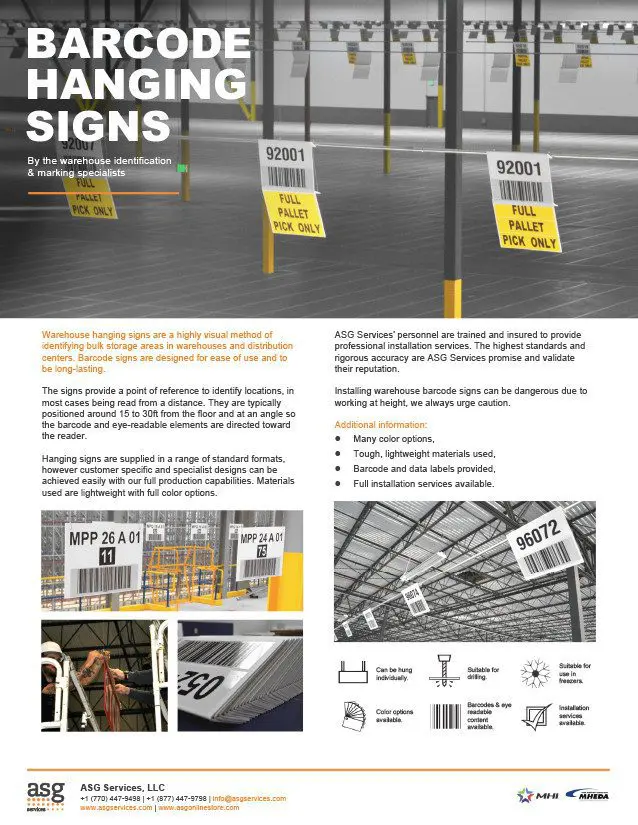

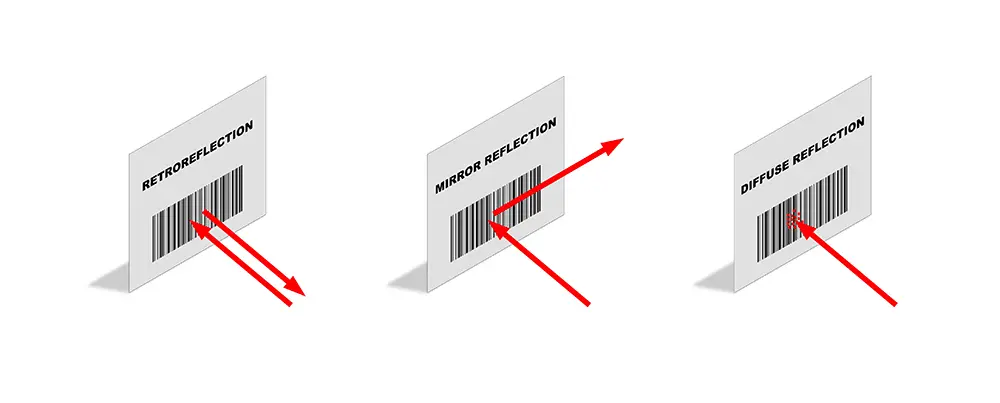

Retro reflective material is unique in enabling long-range scanning, because of the level of reflectivity. Retroreflection is where a material reflects a projected light back along its initial course. The image here demonstrates the principle.

This examples here show a warehouse sign with a barcode printed on retro reflective rack label material. On the left, the sign sits in the dark, on the right light reflects to the source, making it easier for scanners to read the barcode.

What Does This Mean for Warehouse labels?

The intensity of the returned light to the scanner means it can travel further, enabling the operator to be further away from the pallet rack barcode label. This is achieved using the correct scanner, so we suggest you discuss this with your scanner vendor first or request a sample label from us to be sure your scanners can handle them.

It enables us to create and scale barcodes to consistently achieve long-range scans and to determine the size of the barcode required, based on the label size. Label size is an important factor with retro-reflective pallet rack labels, it can make a big difference in cost, so we always look for savings for our customers.

Reflective Rack Label Design.

Our custom designs meet your specific needs. We are the leading manufacturer and installers of warehouse labels, with full-service provision to help take your project from idea to completion. We guide customers on layouts, location reference files, proof documentation and installation planning support.

Every customer’s request is considered carefully before we recommend the best fit design, material and durability required for the specific use. Reflective rack labels are often combined with aisle signs, barcode signs and other products to create unique warehouse identification solutions.

Rack Label Installations.

ASG Services is renowned for installation project management services.

We provide professional, fully managed and insured installation teams throughout the USA, who install location identification products daily. Their attention to detail and understanding of warehouse location number sequences is essential in achieving the volume and accuracy they are capable of.

Resources & Takeaways

Downloads

Help & Advice

Frequently Asked Questions

How far away can I stand and scan them?

Warehouse barcode signs are location signs equipped with long-range material used to print the barcode on. The material allows the user to stand around 49ft to 65ft away and scan the barcode with ease, if their hardware is equipped with the relevant components.

How do I build a rack location data file?

If you are not able to generate a location file from your warehouse management system, we recommend you use a spreadsheet to help build your own. Spreadsheets allow you to use columns to separate the location sub references, and the rows to quickly expand the number of derivates per run.

These columns of data can then be combined to create the barcode data and separately to create the readable elements with separators so operatives can read the rack and shelf location names easily.

Read more on how to build a warehouse location data file.

If you need a little help, browse our online store and find rack labels of all types for a quick purchase experience. Our products are crafted with technology for trusted durability.

Find more…

Contact us and discover how we can help.