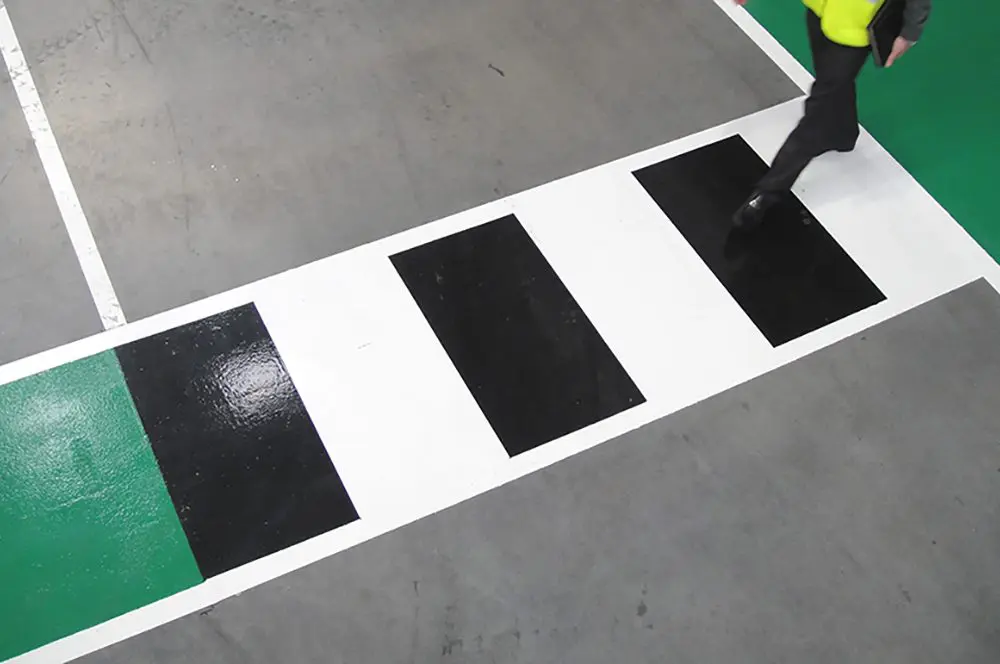

Striping

Epoxy Floor Coatings & Battery Charge Areas

Throughout the warehouse and distribution industry, ASG Services have provided floor coatings for new and existing facilities.

Project managed installations throughout the US.

Warehouse Floor Coatings.

Throughout the warehouse and distribution industry, ASG Services have provided floor coatings for new and existing facilities. Customers use coatings as a protective system or as a repair technique. Our methods are durable, resistant to oil and chemical spills, not to mention acid damage caused by forklift truck battery leaks in battery charge areas.

All high-performance coating systems must be applied over a prepared surface. ASG Services utilize specialist concrete preparation equipment to remove the smooth floor surface which may be brand new or has become contaminated over time. Removing the surface provides a fresh and roughened finish which the epoxy paint coating systems key or adhere to with much greater effect.

Epoxy paint coatings are used throughout industry to create durable and chemical resistant surfaces which are chosen for battery charge areas, manufacturing and re-manufacturing areas and for high traffic pedestrian routes where the floor and surround areas must be kept clean and dust free.

A huge range of colors are available. Our customers typically choose grey for warehouse use and dark red for floor coatings in food preparation areas. Thanks to the materials we use, we can apply striping and other markings to the new coatings with exceptional performance.

Various designs of markings can be achieved on top of a coated floor, including:

- Staging lanes

- Storage lanes

- Numbering

- Dock bays

- Hatch areas

- Pedestrian walkways

- Fire exits

- Walking men stencils

- Forklift parking for battery charging

Installation Project Management.

Our project management team handles all coating projects and is always careful to plan installations with specific attention on the customer’s operation. In new facilities, the operation is usually unaffected as it is not yet functioning, however in existing warehouses and distribution centers, downtime costs money. The project teams will present drawings with areas identified as ‘per-day’ work, allowing the customer to prioritize and schedule areas for a sequence which impacts least.

The installation team’s ability to work to the floor coatings schedule and to adapt at the last minute makes ASG Services one of the most truly dynamic suppliers you can deal with. Their constant communication with the project teams and customers ensure everyone is up-to-date and able to respond to changes.

All teams are fully trained and insured to work on all customer sites throughout the US and beyond.

Help & Advice

Frequently Asked Questions

How long will it take to install?

Our project teams are able to forecast, with a good level of accuracy, installation times of all products we produce and the floor markings we create.

Many factors come into the calculation as you might expect, such as quantities, dimensions, etc, so a detailed discussion will be needed to develop the time frame. We use this framework for all our project planning as we know our speedy completion is often the last in the larger process.

What colors should I use?

OSHA recommends the following:

- Yellow. – Yellow shall be the basic color for designating caution and for marking physical hazards such as: Striking against, stumbling, falling, tripping, and “caught in between.”

- “DANGER” – Red, or predominantly red, with lettering or symbols in a contrasting color.

- “CAUTION” – Yellow, or predominantly yellow, with lettering or symbols in a contrasting color.

- “WARNING” – Orange, or predominantly orange, with lettering or symbols in a contrasting color.

- “BIOLOGICAL HAZARD” – Fluorescent orange or orange-red, or predominantly so, with lettering or symbols in a contrasting color.

Most work carried out by ASG Services is done with yellow and/or white. Occasionally we will be asked to use red, green, blue and grey. If in doubt ask what we can provide, almost any color is available.

What preparation is best for my warehouse?

Preparation helps improve durability, so if you are operating a very busy facility or moving items which are heavy, you will likely need a preparation method.

There are several options to consider:

- Heavy traffic areas – consider embedded striping,

- High traffic – consider shot blasted,

- General and low-level traffic – it may be possible to use an epoxy directly on a cleaned surface. However, this has a low durability rating as with tape.

It is typically more cost effective to have a preparation method when compared to several years of re-coating and touch ups which will be needed.

Why should I consider integrated markings?

Combining your storage markings with passageways or safety markings can help save money over time. This comes from shared demarcation boundaries and downtime during installations, plus reduced mobilization, plant hire and material costs.

Case Studies

We’ve helped hundreds of companies

Case studies from some of our customers who are improving their warehouses.

Our Client List Keeps Growing!

Shop now for reliable, high-quality products crafted with technology for trusted durability.

Find more…

Contact us and discover how we can help.