Labels

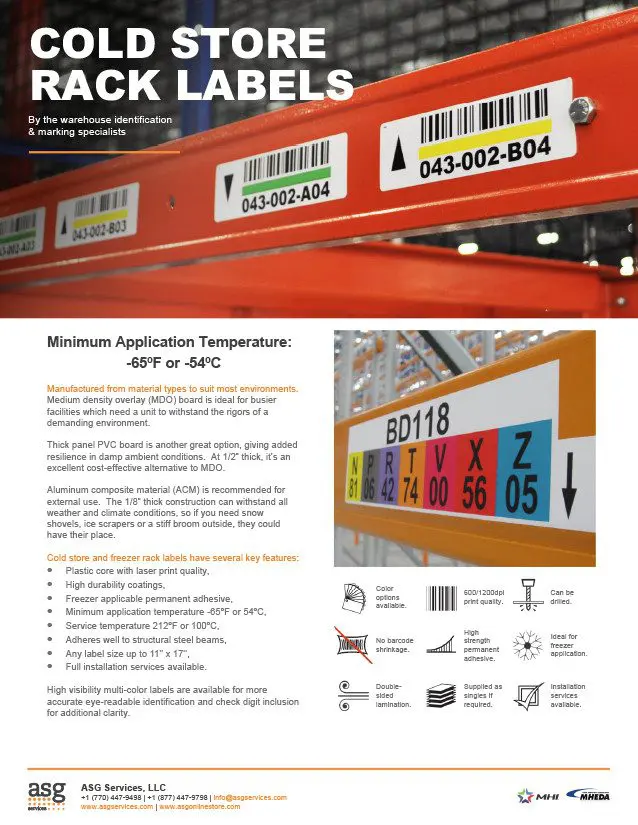

Cold Storage Rack Labels

Application temperature: -20ºF (-30ºC).

Service temperature: -65ºF to 200ºF (-54ºC to 93ºC).

Designed and produced in-house, and installed throughout the US.

Cold Storage Rack Labels.

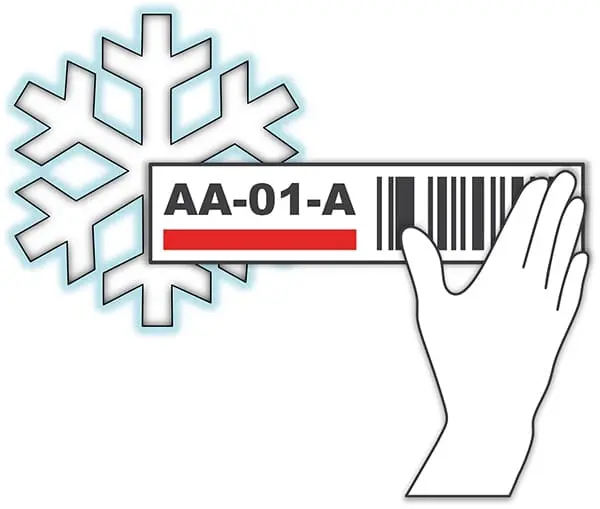

ASG Services have worked closely with adhesive manufacturers and users of industrial cold storage facilities to produce a unique freezer grade rack label which can be applied at -20ºF (-30ºC).

This has been a breakthrough for customers as it allows them to carry out warehouse labeling in freezers without heating the beams or increasing the facility temperature.

The food and beverage industry form our largest customer base of this unique product. However, we also provide companies with external racking where ambient temperatures can be extremely low and the need for a specialist adhesive is just as important.

We take a custom approach to all products and services to meet the needs of customers. Therefore, we can create more than just a label with freezer grade adhesive, we can also carry this over to signs and floor tape.

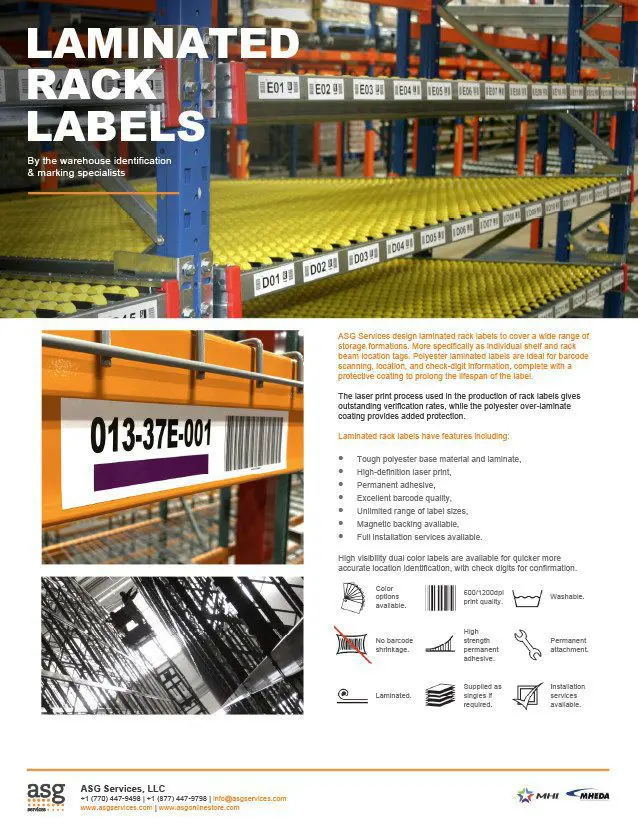

You can also view more of our rack labels here.

Freezer Label Design.

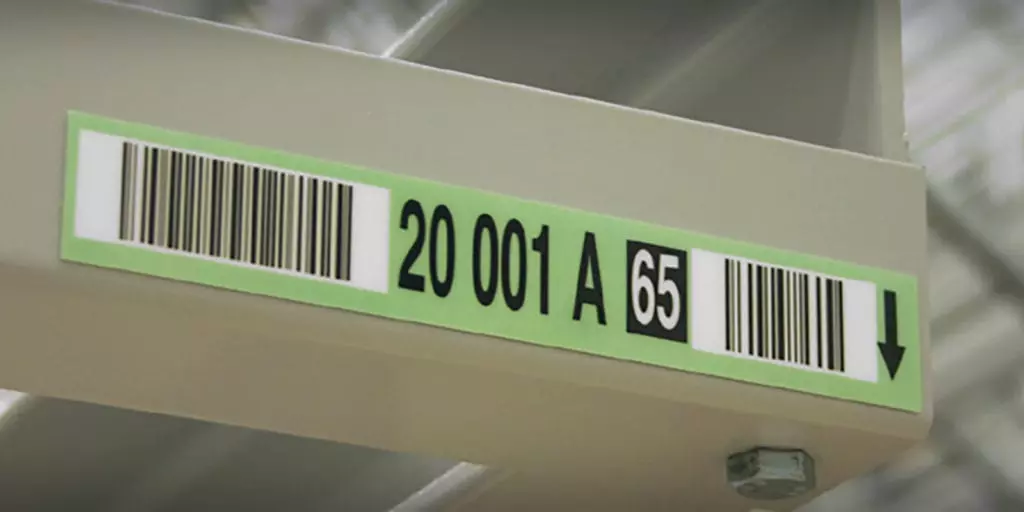

Cold storage rack labels are designed to suit customer specifications or from tailored designs, generated from ASG Services’ vast experience and project archives. Mono and full color designs are possible thanks to continued investment in the latest high-definition print technology. Our specialist software allows us to handle large quantities of variable data used to create multi field freezer labels.

Freezer Grade Adhesive.

We believe the adhesive used is unique to ASG Services. The reinforced adhesive has an exclusive chemical construction which is key to such low application temperatures. Once applied, the adhesive bonds with such strength that it is incredibly difficult to remove the cold storage rack label, which is perfect for longevity.

In-House Production.

In conjunction with high performance materials, ASG Services focus on high performance print. Barcodes printed using high-definition machines outperform others in verification tests, which means customers do not need the latest scanning technology to get a scan first time.

Materials are critical for high-performance freezer rack labels which test and approve periodically.

A plastic composite is the most popular as they offer supreme durability with a seven-part construction. Freezer labels are rarely removed from rack and shelf bream faces. Therefore, it is extremely important the durability level is high, in order to withstand damage and so the barcode remains scannable.

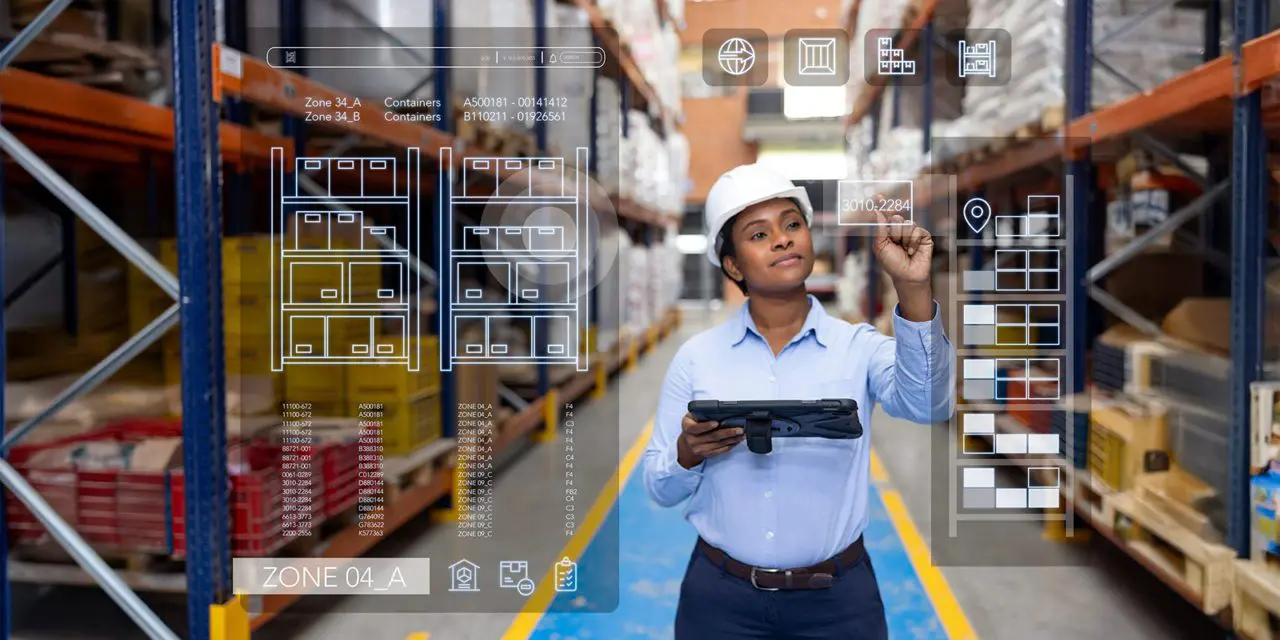

Services

Warehouse Freezer Label Installation Services.

Our cold storage rack labels have been applied at -20 degrees Fahrenheit, which is the typical operating temperature of our customers’ facilities.

The installation of labels in industrial freezers is not for amateurs or temporary staff.

ASG Services’ fully trained and insured installation teams can apply all kinds of warehouse labels on all customer sites. Armed with thermal suits and knowledge of the dangers working in freezer stores can bring, they give our customers peace of mind and a successful completion to the freezer label installation.

Contact us to discuss your needs or visit our pallet rack label installation page for more information.

Resources & Takeaways

Downloads

Our Client List Keeps Growing!

Help & Advice

Frequently Asked Questions

My labels will not stick, what can I do?

It depends on several things, the cleanliness of the surface, the surface texture and temperature.

The surface must be free from dust and dirt, oil, cleaning solutions and moisture and any coatings which are loose.

The surface texture is important, for example standard adhesives will not stick to an unfinished wood surface or a galvanized surface where microscopic elements prevent the adhesive working. Additionally, a surface which is very uneven, like a rough plastic mold finishes, does not provide enough flat surface area for the adhesive to bond.

Finally, temperature can affect the adhesive. In very cold environments, including chillers and freezers, the elements of the adhesive begin to freeze. Fortunately, they do not neutralize, so once warmed they can be used.

Which warehouse label can I use on the floor in a cold store facility?

We produce self-adhesive floor labels which are of a durable grade for use on warehouse floors, and we have combined these composite labels with special low temperature adhesive, which work in extremely low temperatures. They are ideal of use in cold store facilities and freezer chambers. We recommend you thoroughly clean the floor surface prior to application and only take the labels into the freezer once you are ready to apply them for maximum performance.

Our high-performance freezer adhesive is suitable for application at -20ºF (-30ºC).

Contact us and request samples.

How do I build a rack location data file?

If you are not able to generate a location file from your warehouse management system, we recommend you use a spreadsheet to help build your own.

Spreadsheets allow you to use columns to separate the location sub references, and the rows to quickly expand the number of derivates per run. These columns of data can then be combined to create the barcode data and separately to create the readable elements with separators so operatives can read the rack and shelf location names easily.

Read more on how to build a warehouse location data file.

Find more…

Contact us and discover how we can help.