Articles

Naming Warehouse Storage Locations

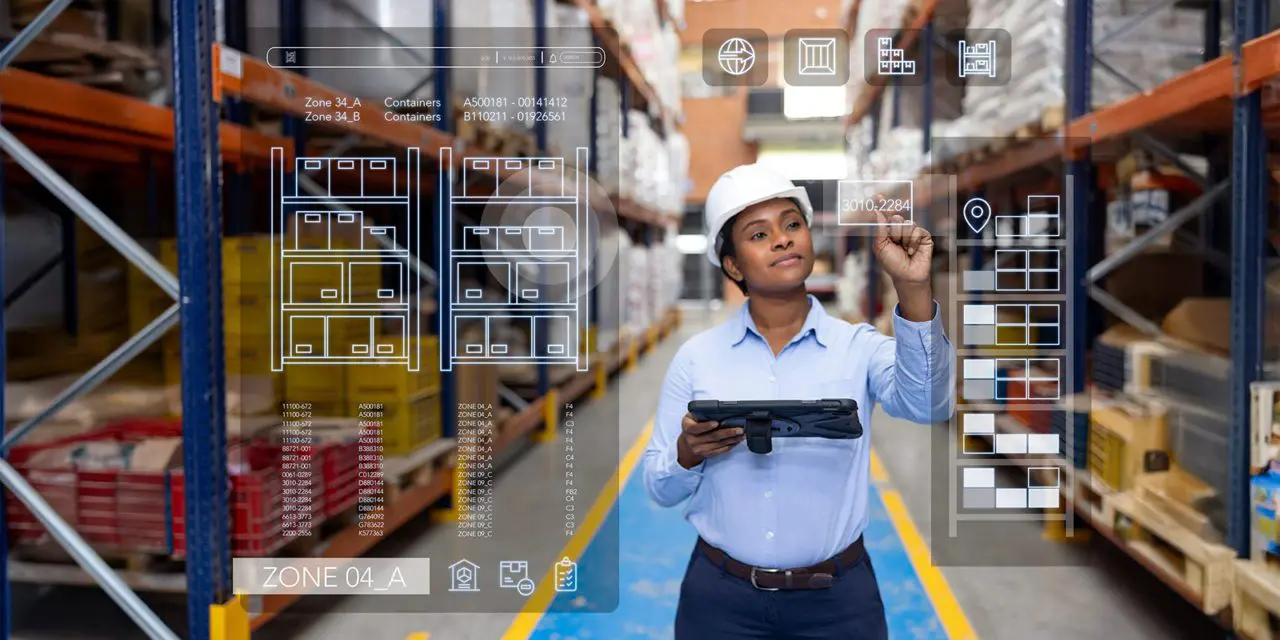

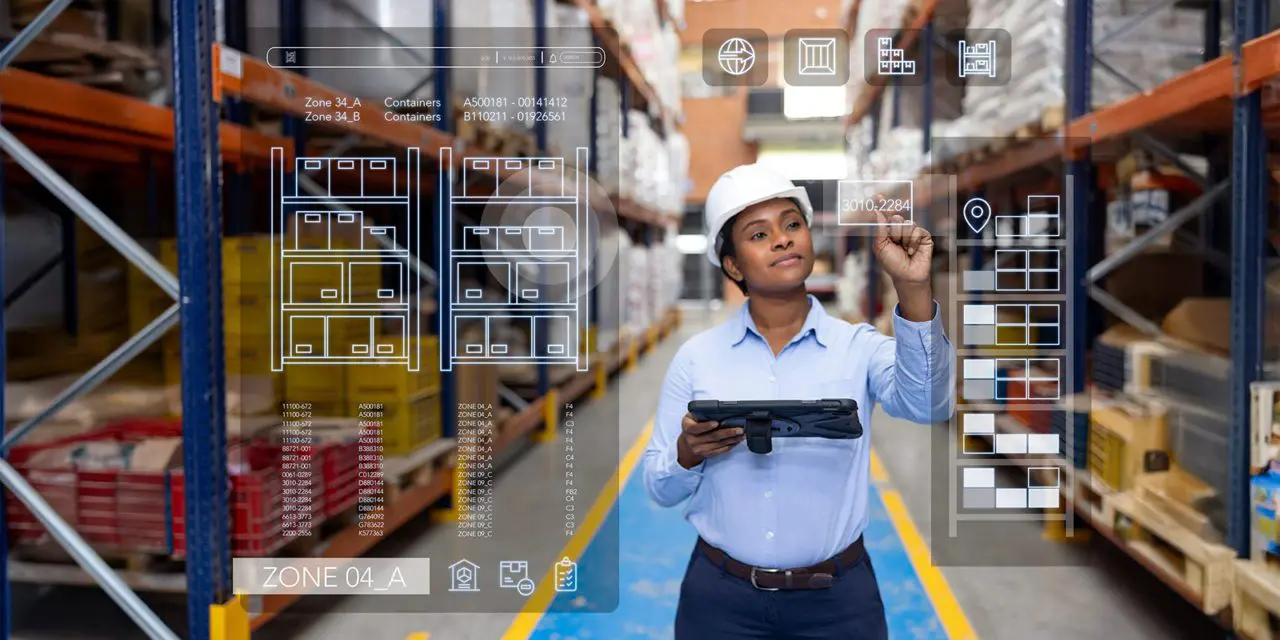

Warehouse identification and floor marking system

Overview:

Dynamic Orderliness.

Today’s dynamic logistics centers are not just shelves full of boxes, they are meticulously designed environments. They handle goods of unimaginable variations and are refined for supreme efficiency every day of the year. Those items may be moving through the facility quickly, in and out within days, or may sit on the shelf for weeks, months and in some cases, years.

These facilities are in the business of handling and storage, where space optimization, and minimizing movement affect profit margins considerably.

Specialists and consultants are used to analyze historical inventory volumes and movements which provide them with the insight to help design and maximize facility potential. Their understanding of the industry, product knowledge and intrinsic focus, results in optimal layouts which are highly valued. Bringing specialized handling and storage systems, rack configurations, MHE routing flows, and floor storage, changes the building from a box to living environment.

These are the foundations on which most buildings run throughout their lifespan.

Why Naming Locations Matters

Like with any complex universe, these facilities need order to be understood. Knowing where to put a pallet, case, or individual parts is critical and none more so in facilities with hundreds of thousands of locations.

Each location therefore needs to be named!

It is not unusual for small companies to have a person who oversees the warehouse and knows where everything is. It makes sense until they go on vacation, or load-volumes take over. Implementing a warehouse management system (WMS) then becomes the right thing to do.

Large businesses go through similar processes, even when using a WMS or enterprise resource planning (ERP) system. The software capability must be in line with business scale.

Ultimately the storage locations need a name or reference. The reference is often based on a grid convention, like that used on a map and in most cases with a third dimension for vertical storage.

Employing simple reference structures helps with ease of use. An operative who can read the reference easily, identify where the location is, and move to it quickly, is far more efficient than one who stops moving while deciphering the code, and then searches for the location, like it is a lost treasure.

Having a numbering scheme helps in other ways too. In more sophisticated operations, where shelf-life matters, an ERP can prioritize with a FIFO pick sequence. A numbering system is therefore essential for placement and retrieval.

What a Location Reference Is

The references created for numbering a warehouse are like the address for a home. It’s a combination of area names, which zero into the unique place.

For example, DC is the state, Washington is the city in the state, 20500 is the area in the city, Pennsylvania Avenue is the road in that area, Northwest tells us which end of the road, and 1600 is the number of the house: The White House, Pennsylvania Avenue NW, Washington, DC 20500.

There is no set rule on how to configure your references. Many factors come into play, for example, floor storage may follow on from racking references, or they may be given a different pre-set to identify the zone, for example

How You Might Create a Location Naming Convention

Floor storage references often start with:

| The aisle number or letter: | A |

| Then, a lane or slot number or letter is added: | 001 |

| And maybe, a lane or letter, if needed: | 1 |

Barcode Hanging Sign Layout

Floor Label Layout

This presents the first location reference in your floor storage layout and would read A-001-A on the floor label or hanging barcode sign, making it easy for people to read. A001A would be the barcode content used in your software system. They are different as the software programs, typically, do not use symbols or punctuation.

A rack or shelf numbering scheme may consist of similar, for example:

| The aisle number or letter: | A1 |

| Then, a position (on the beam) number or letter is added: | 001 |

| Then a level number or letter: | A |

| And potentially, a depth reference for systems like push pack racking: | 1 |

Pallet Rack Label Layout

This would be the first location reference on your shelf or rack beams and present as A1-001-A-1 on the label, or A1001A1 in the barcode.

There is no set rule on how to configure your references. Many factors come into play, for example, floor storage may follow on from racking references, or they may be given a different pre-set to identify the zone, for example

- FS (floor storage), or

- PR (pallet rack).

Other influences are possible, such as

- OH for the building location,

- GM for General Motors as the end user,

- D for dry goods category,

- CS, for cold storage temperature, etc.

These are just some examples of reference additions some customers have used for their location labels.

Implementation & Software Integration

The software may also dictate the references, so if you are using a consultant or WMS specialist, it would be wise to take their lead.

There are several options for building your location reference file. Often, this is a labeling system derived from the building operator or with specialist consultants. Once a convention is found, it is submitted to the software teams to begin their work.

The software specialists generally present the official data with omissions to companies like ASG Services. ASG’s project teams then set about their own cross-reference checks, using building and structural layouts to ensure all locations are referenced. This helps clarify the product type to be used and installation scheduling.

ASG Services can build them using rack and shelf profile diagrams and floor layout drawings, for them to be approved by consultants if needed.

Rapid developments in software and AI now make it possible for warehouse location files to be completed within minutes of entering the relevant details. These game-changing introductions will drastically improve go-live dates and pre-work costs.

Take the Next Step

Product considerations when implementing a warehouse numbering scheme, develop to meet the needs of the user and the information need within the product. ASG Services custom approach to product design and development is met with quality assurance and durability from their in-house manufacturing capabilities. Their focus is on customer satisfaction that results in repeat orders, not quick wins.

ASG Services produce custom warehouse labels and custom warehouse signs. The company has decades of experience in warehouse identification, numbering, production and installation services.

Start the conversation with our team. We help many companies with basic and complex questions, before ever starting a project with them. If you want to talk something through, or if you are ready to begin your project journey, feel free to contact us and initiate the process.

Resources & Takeaways

Downloads

Our Client List Keeps Growing!

Find more…

Contact us and discover how we can help.