Striping

Shot Blast Floor Striping

ASG Services most popular method of warehouse striping is unquestionably shot blast floor striping.

Providing Striping Solutions Throughout the US

The preparation method of shot blasting the concrete surface to remove the top layer, combined with a coating of epoxy resin compound, is the most cost-effective high-performance striping solution available.

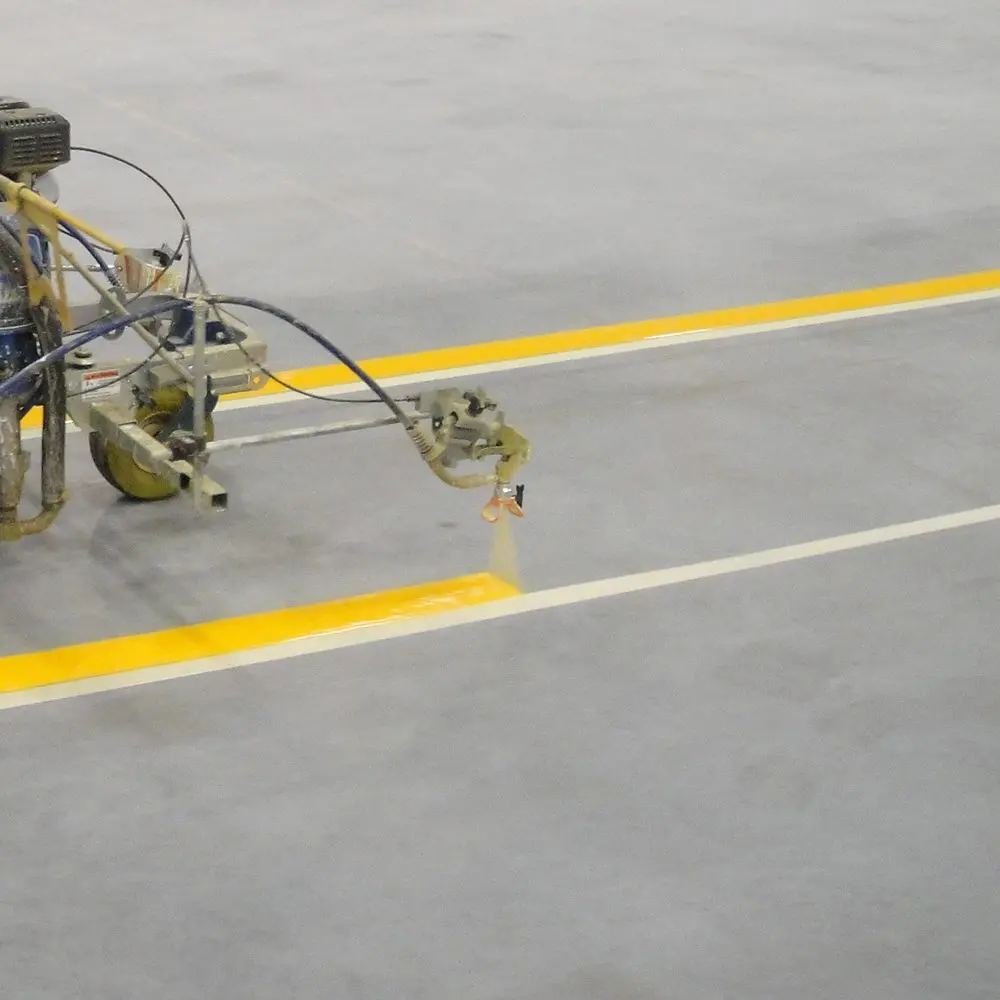

Our investment in the latest floor preparation developments means ASG Services can remove very precise amounts of concrete floors, to specific widths. Shot blast floor striping installed using this equipment, prevents the floor from being left unsealed, since the blast face is the same width as the coating applied.

Accuracy and control are key, which is why we spend time and money on the best equipment, training and people to provide the high-quality product expected.

What is Shot Blast Floor Striping?

Our shot blast machine fires highly control shot at the concrete within a captive system. On impact, the concrete surface breaks away in fine parts, revealing a fresh and roughened surface beneath.

This process is clean and controlled by a vacuum system, preventing dust and debris from leaving the machine.

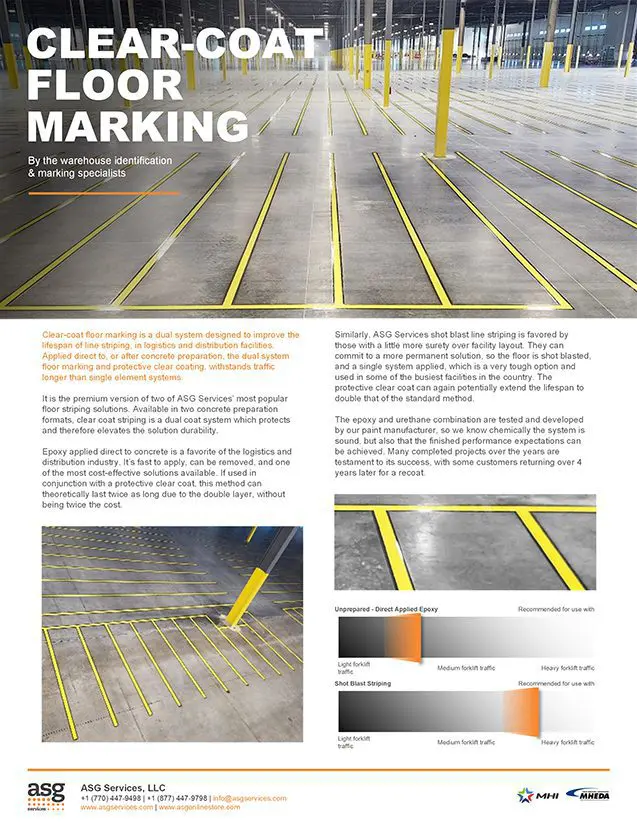

Blasted Concrete Floor Prior to Paint Application.

In this picture, you can see lines that have been created on the concrete floor. This is where the smooth surface of the concrete has been removed, so you are not looking at paint, instead you can see fresh concrete that we apply paint to.

Choosing the Right Paint.

The chosen paint system is then sprayed or roller applied, creating one of the most durable floor striping systems available.

Forklift impact is massively reduced thanks to the low profile of the shot blast floor striping method. The paint also forms a far greater key or adhesion with the prepared surface, making the bond incredibly tough. The system is not indestructible, however customers typically contact ASG Services between 4 and 5 years after installation, for a re-coat.

Shot blasted floor striping can be removed and the floor resealed, or customers can simply have the markings grayed out.

Additional durability can be achieved, visit our Clear-Coat Floor Marking page for more information.

Services

Line Striping Installation Services.

All warehouse floor striping projects carried out by ASG Services are treated with the same meticulous attention to detail and consideration. Our customers are unique, each operating in different ways, so we provide floor layout maps showing areas to be completed per day, which can be prioritized in conjunction with stock movements and requirements.

Before all floor striping installations, we ask customers to clean the floor thoroughly ahead of our teams arriving. This is the case with all types of floor marking work, including shot blasted floor striping as we often use adhesive tape to mask areas of the floor prior to applying the paint system.

Our project and installation teams work as one to ensure the installation maintains continued progress, there are occasions where customers are unable to allow access for one reason or another, which is why we focus on a flexible planning approach.

All ASG Services installation teams are fully trained and insured to work on all customer sites and have the knowledge and expertise to provide a complete shot-blast floor striping installation by the deadline.

Resources & Takeaways

Downloads

Our Client List Keeps Growing!

Case Studies

We’ve helped hundreds of companies

Case studies from some of our customers who are improving their warehouses.

Help & Advice

Frequently Asked Questions

What colors should I use?

OSHA recommends the following:

- Yellow. – Yellow shall be the basic color for designating caution and for marking physical hazards such as: Striking against, stumbling, falling, tripping, and “caught in between.”

- “DANGER” – Red, or predominantly red, with lettering or symbols in a contrasting color.

- “CAUTION” – Yellow, or predominantly yellow, with lettering or symbols in a contrasting color.

- “WARNING” – Orange, or predominantly orange, with lettering or symbols in a contrasting color.

- “BIOLOGICAL HAZARD” – Fluorescent orange or orange-red, or predominantly so, with lettering or symbols in a contrasting color.

Most work carried out by ASG Services is done with yellow and/or white. Occasionally we will be asked to use red, green, blue and grey. If in doubt ask what we can provide, almost any color is available.

Will I need to give you a drawing? How detailed should it be?

For the most accurate price and planning, it is best to give us as much as possible, having a drawing helps you visualize and us to plan and quote. CAD are easiest as we can use them to pull measurements from, while PDF with measurements added is another great way to provide us with the information.

However, this is not essential, we can help with basic depictions or arrange for a partner firm to visit site and create a much more detailed drawing, contact us for pricing.

How long will it take to install?

Our project teams can forecast, with a good level of accuracy, installation times of all products we produce and the floor markings we create.

Many factors come into the calculation as you might expect, such as quantities, dimensions, etc., so a detailed discussion will be needed to develop the time frame. We use this framework for all our project planning as we know our speedy completion is often the last in the larger process.

Do line widths matter?

Line widths are not critical, but there are several considerations to make, some are as follows:

- OSHA considers lines of 2 inches and greater to be acceptable to provide floor markings for aisles and passageways.

- Narrow lines become more difficult to see inside buildings.

- Four-inch-wide lines are standard through the logistics and distribution industry.

- Narrow lines wear out quicker as there is less paint on the floor.

- Very wide lines may need an anti-slip aggregate finish applied where moisture is present.

Other considerations:

- A more visible marking on the floor draws more attention and so heightens safety.

- The layout measurements must include line widths to ensure a pallet fits within the markings. Pallets on markings can damage the line.

- A narrow line needs less material so is cheaper.

Looking for simple do-it-yourself floor striping products?

Browse our online store for adhesive floor tape, signs, pallet markers and more crafted for trusted durability.

Find more…

Contact us and discover how we can help.