Articles

Why use a Warehouse Labeling Specialist?

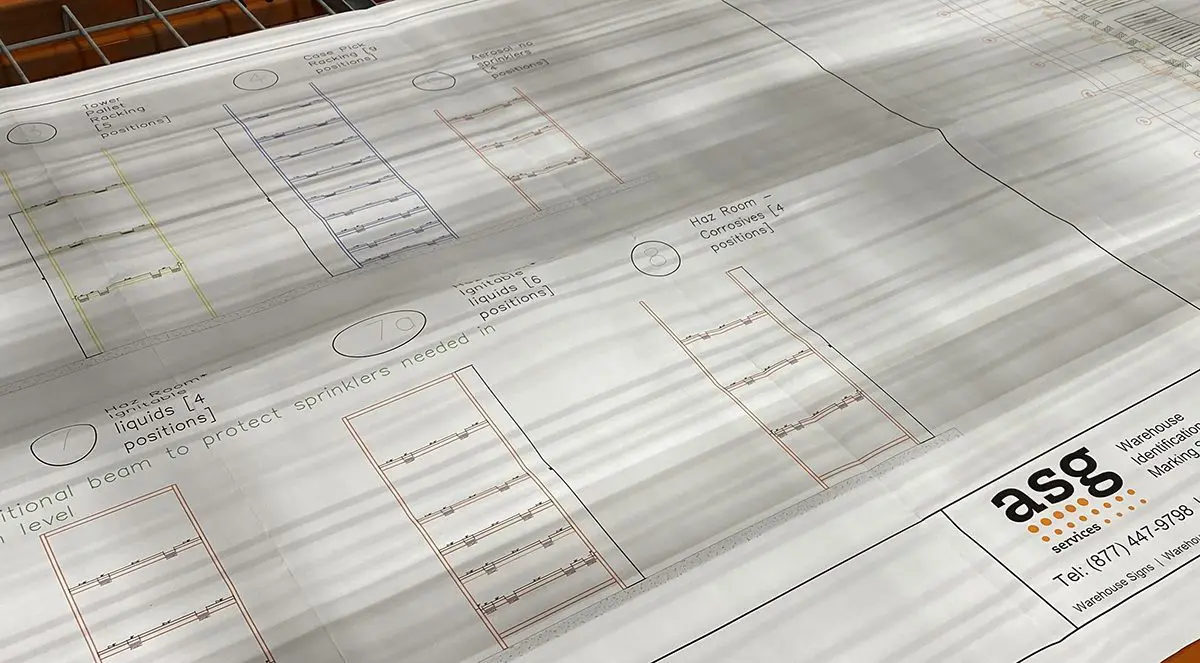

Warehouse identification and floor marking system

Why Use a Warehouse Labeling Specialist?

Overview

Efficient, Cost-Effective and Accurate

Warehouse labeling projects are better when a specialist is used. Industry best practice experience, in-house production and fully trained installation employs are key to efficient, cost-effective and accurate completion. They are critically important when planning a warehouse labeling job.

A specialist warehouse labeling company offers a variety of key components which all begin with the initial consultation. First, they will listen to your situation and consider the options. This enables them to provide professional guidance on labeling systems and material specifications that best suit your needs. They can offer production timelines, and create installation schedules, to meet your deadlines or to work around your operation. Not forgetting quality control provisions to help avoid unnecessary delays.

Exploratory Considerations and Ideas

Depending on the information you have available and how integrated you want the specialists to be, a visit to site, or even a face-to-face meeting with samples and drawings, can considerably expand the possibility of exceeding initial plans. ASG Services, one of the world’s leading names in the field, utilize their technical sales team to do just this. They are often at customer sites and head offices, discussing new projects, re-configurations, and system improvement projects.

Warehouse labeling specialists draw on a wealth of experience and from their archives of work. They can create optimized designs for your warehouse labels that bring efficiencies in material usage, reducing costs as well as installation time and therefore labor cost. As a quick example, combining multiple location references on one label means only one label needs to be applied, saving on installation and material costs.

Label Concept, Design and Creation

Warehouse label designs are not complex by nature, however with careful consideration and smart use of space, colors and content mix, they can be extremely effective and introduce a considerable improvement to the professional appearance of a distribution center. Not only is this good for operational efficiencies, but it also improves morale and employee care in their work environment.

Once the design structure is in place, material choices become paramount to the lifespan of a warehouse labeling system. Durability is obviously important, however there are various levels available to suit the label use. Scan-range may be important, so a reflective material may be adopted. If labels are used where sunlight floods in, UV protection will be important. Adhesive type is equally as important, depending on the surface and temperature. These are just some of the considerations a warehouse labeling specialist will have.

Learn more about ASG Services warehouse label designs.

Durable Materials

At ASG Services, the production team turns base materials into finished goods. This isn’t just a nice thing to have, it is a fundamental element in mobilizing a label installation team. ASG for example, can start production immediately, in line with installation start times, where a customer taking an alternative route, may wait weeks for labels to be made, and then more for an installation contractor to be scheduled. This is made possible not only by a dynamic production and installation team, but also by the project managers who work busily in the background, making sure all aspects are addressed and on track.

Project Managed Installations

The project team are also critical in planning installation workflows. minimizing disruption, but more importantly, ensuring their installation teams can work consistently and achieve application rates that meet customer deadlines. The project team’s focus is on the customer and operational needs.

The installation teams are trained in application techniques which are fast, accurate and precise. They are trained in the use of access equipment, working at height, necessary tooling for sign installations, all while observing the safety requirements of ASG and the customer sites.

Reporting to the project teams daily, the two work simultaneously to inform and update the customer of progress, potential issues, and interim checks. This helps avoid delays and disappointment toward the end phases of a job.

Learn about the rack label installation services ASG provide throughout the US.

Warehouse Label Investment

Buying cheap labels and cheap installation labor seems reasonable at first, and in some cases will work just fine, however, if you do not have someone in-house, who can oversee the project from start to finish and who hasn’t had extensive experience of a labeling project, the result may not be what you had in mind, in quality, accuracy and cost.

These are just some of the key features and benefits people can expect when working with experts. The combination of a professional installation and design team, along with in-house production capabilities for all the labels and signs, ensures that customers get the best possible experience when utilizing a warehouse labeling specialist. ASG Services are proud to bring these benefits to our customers every day, with every label we supply and install.

For more information on the dynamic and professional services of ASG Services, contact us on 877.447.9798 or visit our contact page for more details.

Resources & Takeaways

Downloads

Find more…

Contact us and discover how we can help.