Articles

What is a 2D Barcode?

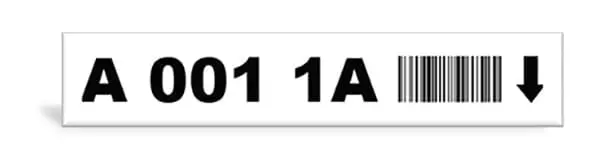

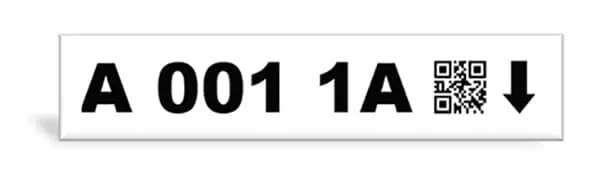

Warehouse identification and floor marking systems

Overview

Understanding the Difference

The two general classifications of barcodes are 1D (one-dimensional) and 2D (two-dimensional) and are used in different types of applications. Different technology is also often involved in reading 1D and 2D barcodes.

The differences in 1D and 2D barcode scanning depend on the layout and amount of data each can store. Both are used effectively across a variety of identification platforms and applications.

1D Barcodes

Universal product codes (UPC) commonly found in consumer goods, are a good example of these. A UPC employs a variable series of spaces and lines to encode data. The linear barcodes can only contain a few dozen characters and get physically longer as data is added. Because of this, they are limited in performance as the bars become compressed and scanning technology struggles to read the separation, therefore they tend to be 8-15 characters in length. Similar is true for other barcode symbology.

In The Warehouse

For location identification, 8-15 characters cover most requirements, however with the rapid growth and complexity involved with e-commerce fulfillment and the intricate storage solutions, the linear barcode is becoming very condensed.

2D Barcodes

QR1 Code, Data Matrix, or PDF417, all use squares, dots, hexagons, and other shapes to encode data. 2D barcodes can contain more data (up to 2000 characters) than 1D codes while appearing physically smaller than 1D. Because data is encoded on both, the vertical and horizontal arrangement of the pattern is read in two dimensions.

The main advantage of a 2D barcode is that it isn’t limited to alphanumeric information. It can also contain website addresses, images, voice, and other binary data. Because they are very small, 2D barcodes are used to mark objects that 1D labels are impractical for.

2D barcodes help track everything from surgical instruments to electronic printed circuit boards. Electronics, medical equipment, and pharmaceutical companies must provide a large amount of tracking information on very small items. U.S. FDA’s UDI rules, for example, call for several pieces of information to be included on certain types of medical devices. Due to their small size, 1D barcodes are impractical for these applications.

In The warehouse

Offering a greater number of characters and uses, the 2D patterns are being adopted by companies who are looking for future proof and others are aiming to reduce costs. The cost saving comes from label size reduction as less space is needed to house the barcodes, which can be large when holding lots of characters.

More intricate label designs can also be achieved. We provide several production facilities with labels that are full of product data and various 2D codes per label. The 2D codes need less space, so more information can be provided without increasing the cost of the label due to size.

2D is Versatile

Industry and medical professions are turning toward 2D barcodes for many reasons, the key to them being their versatility. 1D barcodes are limited to about 20 characters while Denso Wave’s QR Code can hold up to 7,000 digits or 4,000 characters of text.

Only certain scanners can read 1D barcodes while most smartphones, including Android and the iPhone, can easily read 2D barcodes. They can also be used to import data from other files and sources such as MS SQL Servers and MS Office. This makes integrating with your company’s current tracking methods possible.

Other Uses of 2D Barcodes

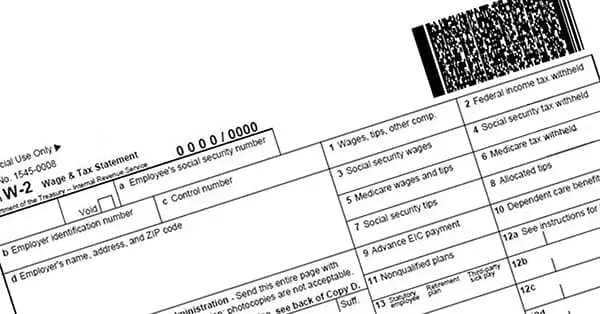

Tax returns

Once tax form creation is completed, it can be printed out along with a 2D code and then mailed to the appropriate tax authority which can then gather data quickly by scanning those codes.

Logistics and distribution

Order data (PO number, product codes, shipping date, quantities, etc.) can automatically be entered into the receiver’s computer, greatly speeding up the process of inventory tracking and data provision.

Driver’s license

A driver’s name, address, license number, expiration date, driving restriction codes, and other information can be encoded in a 2D symbol that is then printed on the operator’s license.

Marketing & promotions

A popular use recently has been by companies using the codes to embed URL’s, addresses, phone numbers, contact names, email addresses, product & service listings and event information for people to scan with a smart devise and that information go to the relevant software database.

ASG Services have helped companies transition from 1D to 2D warehouse identification for many years. We carry out performance testing with customer equipment to ensure verification, scan speed and distance capabilities meet the needs with dimensional restrictions. Optimizing a product ensures performance and cost effectiveness, however we always recommend the most appropriate, and interestingly 1D remains the more common barcode supplied to the warehousing and distribution market.

With lower costs, 2D barcodes are quickly becoming the predominant data storage method. Contact ASG Services with your warehouse label and barcode sign needs, we can help with custom designs and location reference content to meet your individual requirements.

Find more…

Contact us and discover how we can help.