Labels

Warehouse Label Designs

Warehouse barcode labels are created and used for a range of purposes and ASG Services are a leading manufacturer specializing in customized designs to suit each customer’s individual need.

Designed and produced in-house, installed throughout the US.

Warehouse barcode labels are created and used for a range of purposes and ASG Services are a leading manufacturer specializing in customized designs to suit each customer’s individual needs.

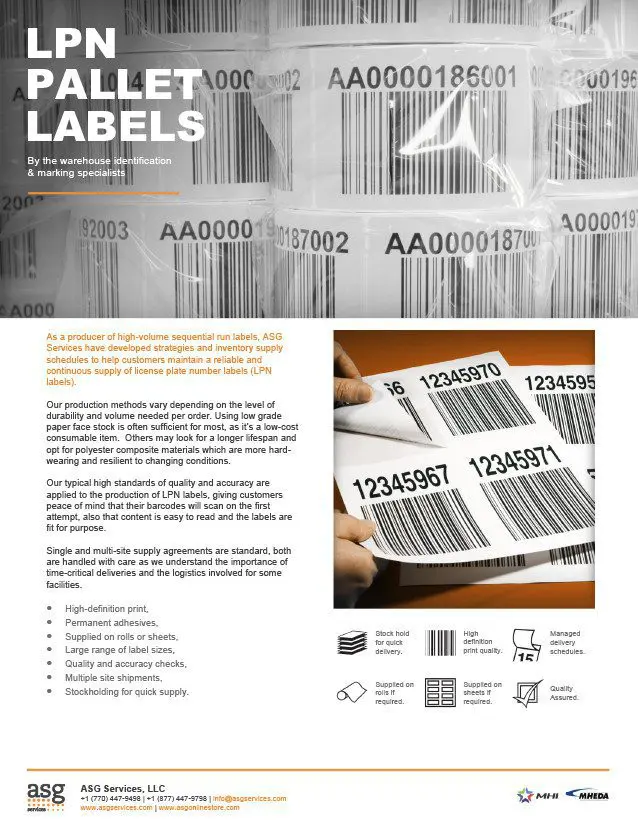

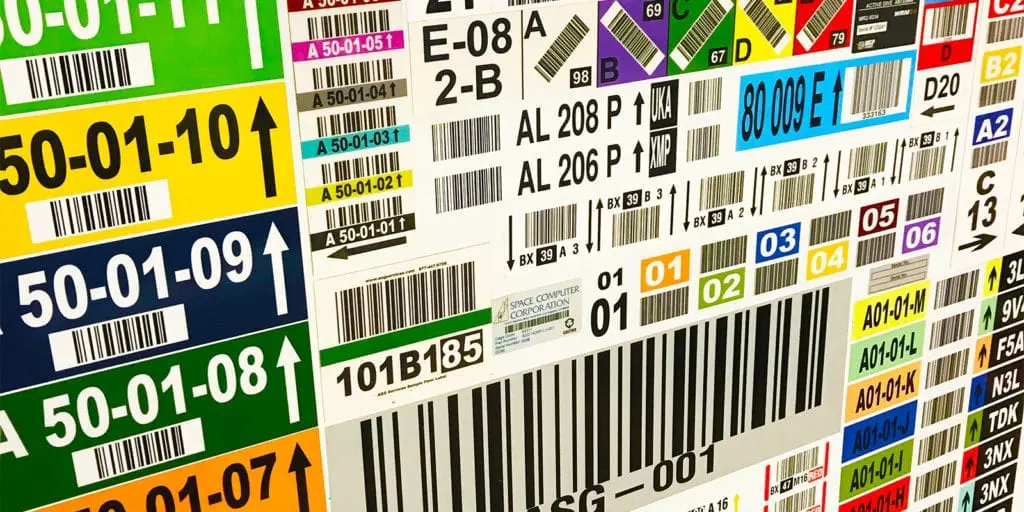

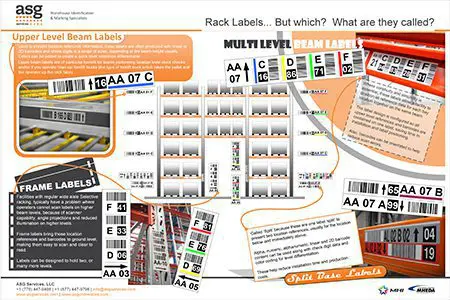

Warehouse labels are used as rack labels, floor labels, shelf labels, pallet labels and product labeling. Most warehouse label designs, created by ASG Services are equipped with barcodes, the most common barcode symbology is Code 128 (high-density) and Code 39 (variable length, discrete) owing to their alphanumeric encoding properties.

The construction of warehouse barcode labels is determined by their use. ASG Services offer varying levels of durability, but with durability comes cost, so we recommend the most suitable durability to suit the need, ensuring costs of controlled.

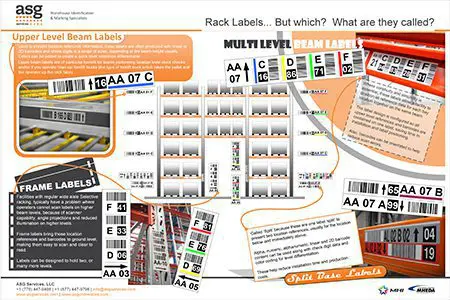

The warehouse label designs created at ASG are also differentiated by their use. Some are needed to present multi-level location references on racking, others are specific to a pallet location or product, while some are unique to a floor location or zone or need check-digit detail.

ASG Services utilize a huge archive of previous designs as recommendations, then fine tune those selected as per the customer’s need. Our design teams are also able to match customers’ existing designs exactly, thanks to the latest design software.

To find out more or to ask advice about your warehouse label designs and ideas, speak with one of our specialists at our head office, outside Atlanta, GA.

From the team

Hi, I’m a Production Coordinator here at ASG Services, it’s a great place to work, we have an amazing staff that is committed to delivering a quality product to our customers which I believe is what sets us apart from other companies in the market.

My daily tasks consist of reviewing orders placed by customers, designing the desired labeling or sign products, either custom designs, or something from our website. I adapt and fine-tune it and once approved the design is sent to our production.

I bridge communication between the sales and production team. My goal is to make sure the customers’ needs are met so they can operate their warehouses efficiently and effectively.

We enjoy the benefits of knowing our customers are getting a great service and product.

Services

Rack Labeling Installation Projects.

Along with custom design and data preparation, our project teams manage installation services throughout the US. Our standards of performance have set industry benchmarks which are reassuring for customers.

The level of accuracy, speed, and quality control which our employees are trained to are unique, as is the fact we employ our own people.

You can read more here, about our rack labeling installations and other label information.

Resources & Takeaways

Downloads

Our Client List Keeps Growing!

Help & Advice

Frequently Asked Questions

What designs can you create?

We are not a graphic design studio, but we can design any label layout required. Variable content data and multi field options are possible, our only restriction on the number of barcodes and characters is the size of label you request. We will always suggest a size which best suits your requirements.

Is color more expensive?

Yes, simply because the raw materials we need to create color labels are more expensive, however once an order is over a certain size, the extra cost becomes negligible.

Why use color?

It is true that location labels do not need color to work, but we recommend color to help the users identify key location information quicker. Color is known to improve speed of identification, to read more visit our warehouse color coding article.

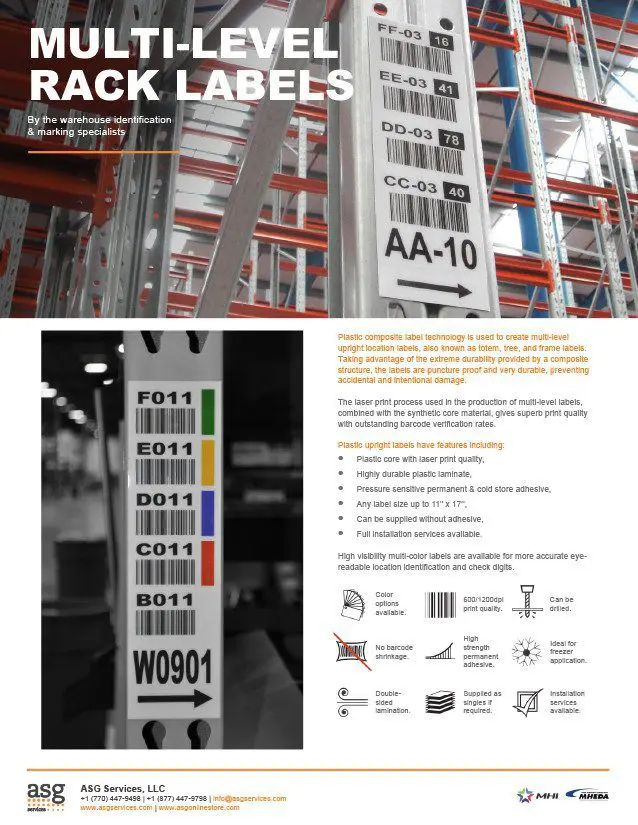

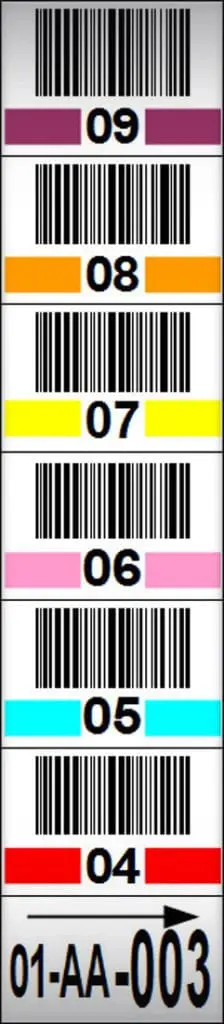

Color identification may be used as a level indicator on racking where each level in a rack bay has a unique color, so as the operative looks up, they can distinguish the level quickly and shorten their reading time. It can also be used as a zone identifier particularly with bulk storage floor locations, aisle groups in racking and shelving are another.

Another well represented use of color is with warehouse striping for staging lanes, bulk storage bays and walkways. See our warehouse striping page for more information.

Some customers use it for aesthetics for their in-house branding.

Which barcode is best?

The barcode you choose to use is dependent on your location or product reference data requirements.

Although we can produce almost any barcode type you require, Code 128 is by far the most requested by the storage and logistics industry. This is in part due to the range of characters which can be used (128), being all digits, characters and punctuation and because of its data to size percentage, lots of data can be stored in this narrow width barcode.

Code 39 is the next most popular, which is less useful in terms of characters it can encode, but it is great for its simplicity and ease of scanning capabilities. This is often used with operations handling product specific references and a need to work quickly.

More recently we have been asked for Data Matrix and QR Codes which can contain huge amounts of data compared to linear barcodes.

Can I have check digits?

Yes, these are common requests from our customers looking for pick accuracy improvements.

What are check digits?

They are ‘digits’ to be double ‘checked’ against the warehouse management system (WMS) records. Once the operative has arrived at the pallet or shelf location, they are asked by the system to provide the ‘check-digit’ information which ensures it matches that on the pick sheet or terminal. If there is a match, it is further confirmation they have found the correct location or product and they are able to proceed with the item pick. If it is a failed match, the operative is prevented from completing the pick task and so knows to look again for the correct storage location.

Check digits are often provided by the warehouse management system, as randomized characters forming an addition to the location code. Most barcodes include a check digit within the symbology, calculated by other characters which form that barcode. In a storage environment, the check digit is typically a separate feature.

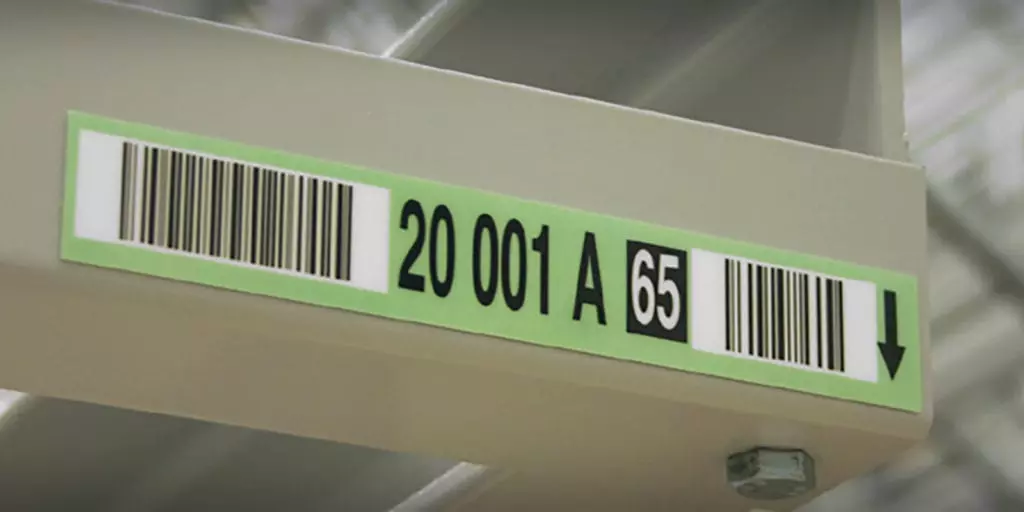

Below, you can see the user check digit presented as characters with a black background on a warehouse rack label and a barcode location sign. The operator reads the location reference, scans the barcode and enters the check digit.

I have a design already, can you copy it?

Yes, if we have a sample or measurements and a good image we can copy your label almost exactly.

Why does label material matter?

Put simply, polyester and polyester composite label material is more durable which prevents barcode distortion during application and shrinkage over time. It also makes it much easier to remove the label, from time to time you may want to re-label your locations due to configuration changes or WMS changes, polyester and poly-composites can be removed without tearing, unlike vinyl materials.

What design or layout should I use?

The options are endless, so it really comes down to the information you want or need to provide. Also, the space available, your budget and how easy you want to make location identification for your team all play an important part.

To save time reading 2000 words on label design call us on (877) 447-9798, to discuss your situation. We can recommend the best solution to suit your needs.

Visit our warehouse labeling pages for more information or our online store where you can purchase online.

Do you need a basic warehouse label design? Need it quick? Shop now for reliable, high-quality labels crafted with technology for trusted durability.

Find more…

Contact us and discover how we can help.