Labels

Warehouse Labeling

Our experience in warehouse labeling and installations allows us to draw on years of expertise through product design to label layouts on the racks.

Designed and produced in-house, installed throughout the US.

Decades of experience in warehouse labeling and project installations allows us to build a platform of product performance, label design, positional layouts on the racks, as well as initial scope of installation progress scheduling.

The variables involved in labeling a warehouse are wide-ranging, which is why companies turn to the likes of ASG Services for warehouse labeling. We help large and small organizations throughout the US, and start our conversations with the intention of thoroughly understanding the operational requirements and expectations.

Taking responsibility.

Initial Labeling Consultation.

Our technical sales team will consider the following:

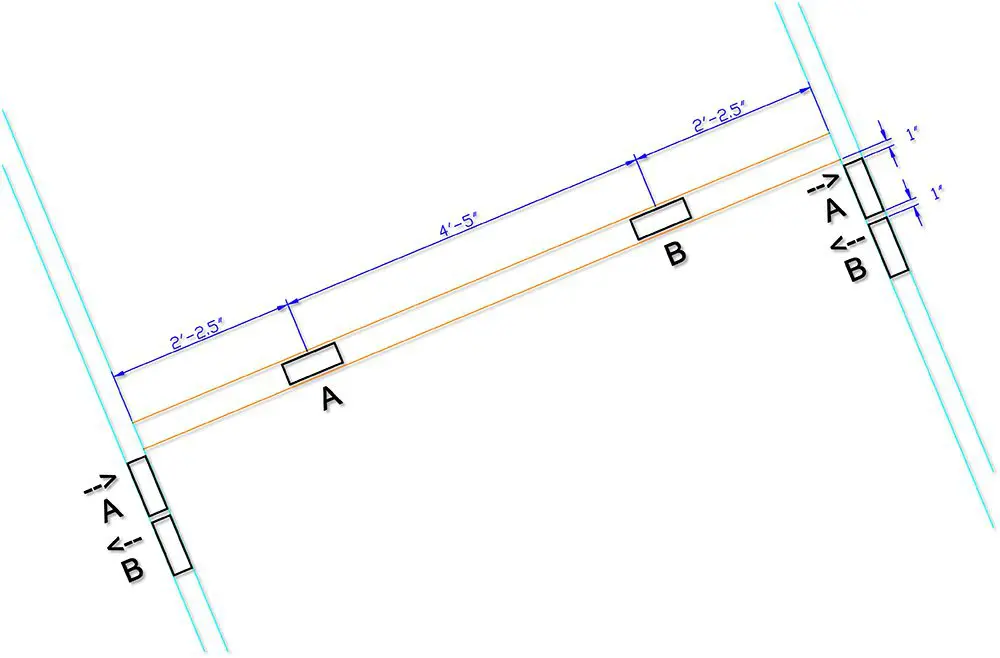

- Facility layout – the operational layout presents flow and interaction considerations for positioning and design.

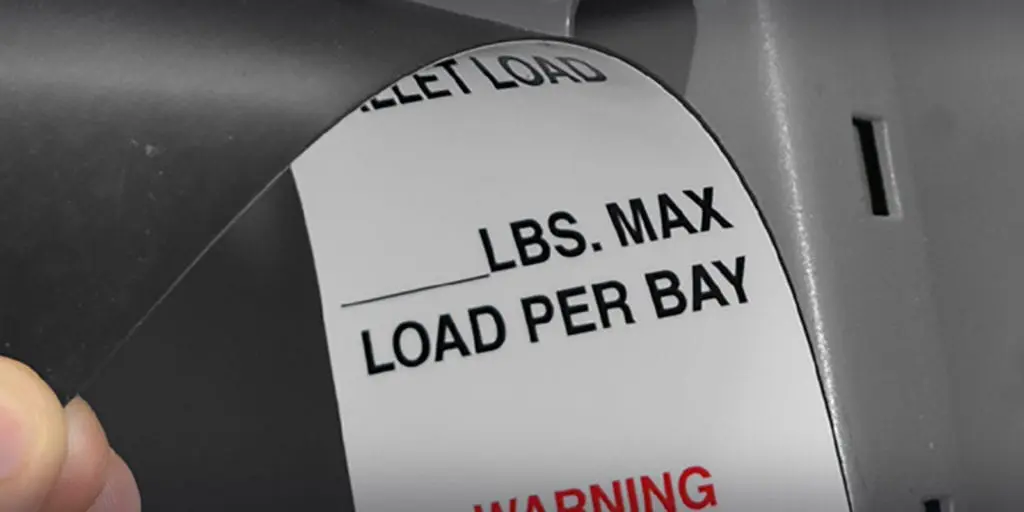

- Storage structure type – frame sizes and profile designs dictate attachment options and the label material and layout type.

- Number system logic – elements of a number sequence more relevant to identify a location can be highlighted in the label design. Sequences effect the installation process, which can save labor costs.

- Pre-existing design formats – replication or evolution of designs may be critical.

Based on this, we will develop plans, recommendations, and proposals that are optimal and ideally, cost‑effective for your needs.

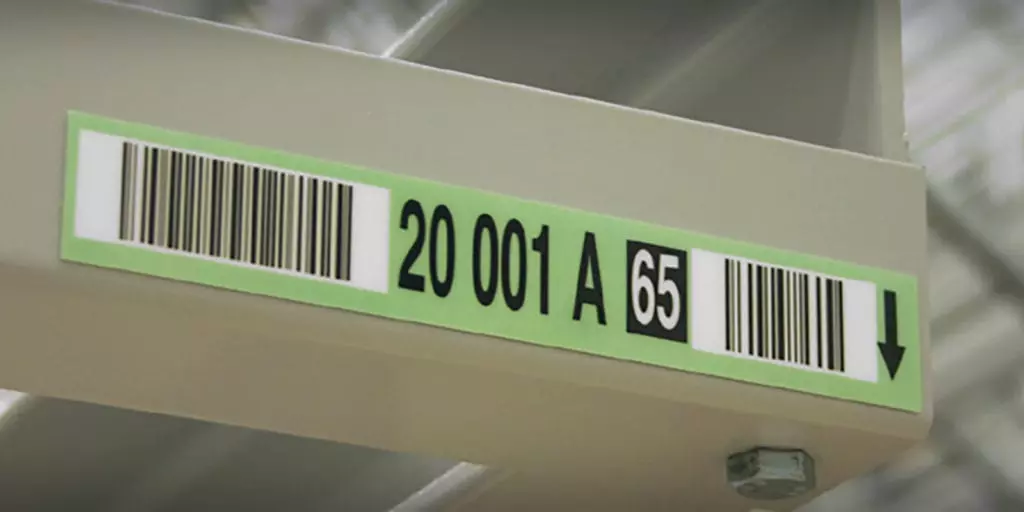

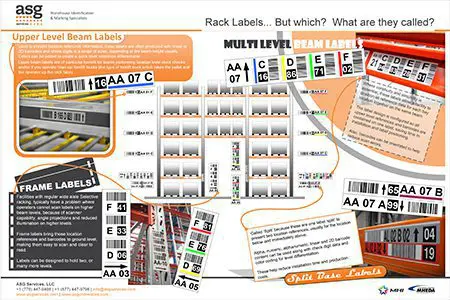

Design

Warehouse labels serve specific purposes. We create different layout designs to help the user see and understand the label design concept. Easy and clear readability is essential, which also ensures the barcode is easy to scan on the first attempt. We understand the consequence of delays, no matter how small, and work to help minimize them.

Some customers already have preferred label designs. Others ask for recommendations. ASG Services’ design team is fully aware and competent of handling your requests, without incremental costs. We always custom-design your labels specific for you. You can read more here about the types of rack labels.

Placement

We position rack labels based on each customer’s system need, the type of shelving or racking design they use, and the label size required. Labels fit precisely and remain readable long-term.

Budgets

In all our warehouse labeling projects, we like to offer the best practice advice which we know works for most of our customers. We also understand budget restrictions mean some customers must make allowances, for which we can also help and provide advice on, with material choices, layout changes, etc.

Early discussions regarding dates are very important at this stage to help with our production planning and installation scheduling.

We offer guidance to all customers during warehouse labeling projects, but when you choose ASG Services to handle your project, we dive deeper, uncovering hidden obstacles and identifying potential errors early on.

Location Label Design and Installation Planning.

The design and planning stage is where our production and project departments become involved and the full complement of ASG Services capabilities are experienced.

Warehouse label designs are put into the proofing stage, where the customer can further alter but also test in practice. Customers may also request actual samples or prototypes, so they have something tangible before final sign off.

During this process, ASG Services technical team will work on the warehouse labeling location file. Most customers will provide a complete inventory of locations, while some may need us to create a location file, based on rack drawings. This is relatively straight forward for our team.

Start your own location data file...

Download this Rack Label Location Date Template – An Excel document.

Pre-Start Preparations.

Once all is signed off and cleared for production, the warehouse labeling project team will also have final discussions with production to determine the sequence and agenda, so the labels are run in-line with the installation schedule.

Rack labeling installations are sequenced on a per day basis. Customers are made aware of achievable quantities per day, and therefore when they can expect sections of their racking to become available for use.

Once this schedule is agreed by both parties, we work in unison to achieve successful completion.

Services

Warehouse Label Installation Management.

The proposal and planning work which goes into our warehouse labeling projects dictate the proceedings for the installation phase. The project management team hands over all information and products needed to the installation manager and assistants, with a complete run-down of details.

Onsite Process.

On the first day, there will be a scouting session where the installation team becomes familiar with the site, attends inductions, and prepares to start. It is during this stage that a final clearance is required from the customer of positioning, starting points, etc.

During the first and second day, metrics are taken by the warehouse labeling installation team and reported back to our head office. Here the project teams make calculations and checks to ensure all is running to plan. It may occur that the customer was unable to give a pre-agreed area, but the team has made up for this delay elsewhere. This can be identified, and the installation reprogrammed accordingly.

Communication.

Most communication between the customer and ASG Services during a warehouse labeling installation will be with the installation team. However, the project teams are always in contact and available to address questions or concerns as well as to update on any changes.

The completion phase often comes earlier than initially planned, thanks to the installation team’s and the customer’s relationship and the understanding that develops, however it is never taken for granted on warehouse labeling installations.

You can read more here about our labeling installation projects and related information.

Each customer is a new challenge.

Improving Warehouse Identification Solutions.

Resources & Takeaways

Downloads

Our Client List Keeps Growing!

Help & Advice

Frequently Asked Questions

If you install the labels, what assurances can I expect?

- Every label will be in the correct place.

- Labels applied to the rack or shelf in a consistent manor for a uniform presentation.

- If you have missed information from your location references, our team will report back to ensure they are made and on site before the facility goes live and hopefully applied before we leave site.

- Barcode and content accuracy.

- Barcode performance and verification guaranteed as an additional service.

What design or layout should I use?

The options are endless, so it really comes down to the information you want or need to provide. Also, the space available, your budget and how easy you want to make location identification for your team all play an important part.

To save time reading 2000 words on label design call us on (877) 447-9798, to discuss your situation. We can recommend the best solution to suit your needs.

What do you need to provide me with a quote?

Quantities, sizes, location, aisle widths, beam heights, building operation status, start date and a thorough conversation so we understand exactly what you are hoping to receive from us and to achieve from using a company like ASG Services.

Do you carry out installations in new buildings?

Yes, in small and large buildings. We are very experienced in working around other contractors on new construction projects and carefully plan our approach with the customers and main contractors to achieve a complete installation.

Do you carry out sign installations in existing facilities?

Yes, this is a specialty of ASG Services. Working in and around a fully operational distribution center can be daunting, not to mention having a significant impact on productivity. Our teams are very experienced in how to work within these facilities and appreciate that the customers’ work ultimately comes first.

Case Studies

We’ve helped hundreds of companies

Case studies from some of our customers who are improving their warehouses.

Looking for standard designs, quick delivery and reliable, high-quality products? Browse our online shop for warehouse labels.

Find more…

Contact us and discover how we can help.