As specialists in warehouse identification and marking products, ASG Services have many years experience in handling warehouse storage data. We work with the data customers provide and where needed can help with the creation of data.

Customers often generate data files from warehouse management software (WMS) or forward those supplied their WMS providers, consultants, etc., following detailed facility survey.

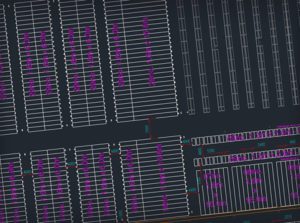

We also receive building layout and rack drawings of their distribution centers and storage facilities showing enough details for us to establish location referencing logic. Using these details and with confirmation from the customer, we are able to build storage location data files which represent all locations required, corresponding to the various rack and shelf labels, barcode signs, floor labels, etc., so we can provide a full turnkey solution.

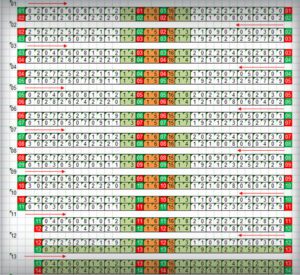

Location data can be very complex and extensive, for this reason ASG Services always works closely with the customer who checks and signs off the data along with product designs, before production begins.

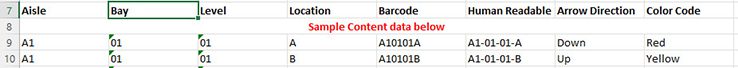

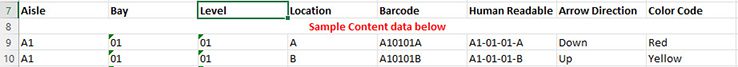

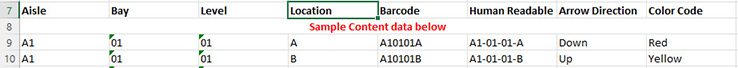

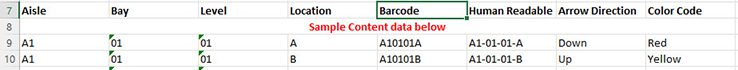

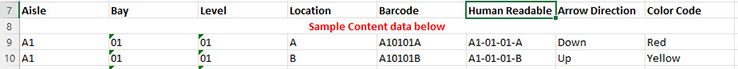

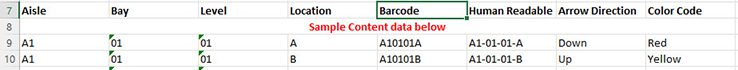

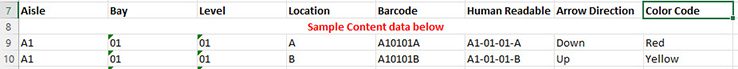

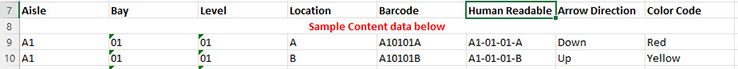

This layout example is to help you build and present your rack label data. We have suggested the following headings, to help with your data gathering and our data manipulation prior to production. Your data maybe configured differently, this is only suggestive.

| Aisle: The aisle reference could be single or multi digit, we used A1, as the first aisle in the row. |  |

| Bay: The bay relates to the space between the rack frame legs, where beams stretch across to create shelves. |  |

| Level: The level number or letter (Number in our example), relates to the storage level. This could be the floor, or the first beam. We have shown 6 levels here, but yours maybe less or greater. |  |

| Location: Within each bay, the slot or location position across the beam, may be 1 to 2, or 3 where pallets are stored, or 01 to 12 or more if small parts are stored on shelves. |  |

| Barcode: The barcode content is often all of the location references combined, in a continuous string, some customers use separation symbols, but we have shown the most common continuous method. |  |

| Human Readable: This information is generally the same as the barcode information, a combination of the location data. However, customers often add symbols and spaces to make the information easier to read by warehouse operatives. |

| Arrow Direction: Where arrows are required, adding a simple Up, Down, Left or Right is adequate. We have shown Up and Down as these are to be used on the beams. |  |

| Color Code: A significant benefit to location identification is in adding a color to denote levels. A simple word reference is best here and where a particular color reference is required, these should be listed separately. Red, #E04116 for example, added to a separate cell at the top of the page, works best. Printed color match can not be guaranteed. |

|

| Barcode Type: Enter the barcode symbology you require, this could be one of many types, so if you are not sure, please ask your system provider, or we can recommend the most common linear or 2D used in the industry. |  |

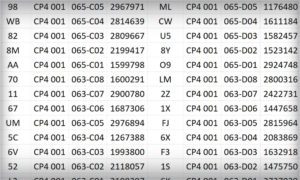

Quantity: If the formula is updated to cover the full list you create, the quantity of labels will be shown which you can cross reference with other location count information. It helps you ensure all are included and shows us what is needed at a glance.

Tabs: At the bottom of the page, we have show a main and a ‘Type 2’ tab. You may name it differently to related to the location type, label size, project reference, etc. Having separate tabs helps us see which data is for which label and helps you check all needed are included.

![]()

Data integrity is the key to any good project and regardless of how we receive it, we will do everything we can to check its as expected and needed, however our production ready versions will not be proofed in the production process, only the latest version we receive from you. Therefore it is critical that you ensure we have the latest available.

Our pricing includes a degree of data manipulation time, however if the data is too complex or problematic, we will inform you of additional time needed and to be charged for. We will also advise of the difficulties so you can reissues the data to avoid those charges.

Please feel free to speak to us about your data, it is very much in our interests to ensure your data is good to go and that we can process the order swiftly, so we are more than happy to help. You can find contact details here.

Yes, these are a common request from our customers looking for pick accuracy improvements.

The barcode you choose to use is dependent on your location or product reference data requirements.

Although we are able to produce almost any barcode type you require, Code 128 is by far the most requested by the storage and logistics industry. This is impart due to the range of characters which can be used (128), being all digits, characters and punctuation and because of its data to size percentage, lots of data can be stored in this narrow width barcode.

Code 39 is the next most popular, which is less useful in terms of characters it can encode, but it is great for its simplicity and ease of scanning capabilities. This is often used with operations handling product specific references and a need to work quickly.

More recently we have been asked for DataMatrix and QR Codes which can contain huge amounts of data compared to linear barcodes.

They are ‘digits’ to be double ‘checked’ against the warehouse management system (WMS) records. Once the operative has arrived at the pallet or shelf location, they are asked by the system to provide the ‘check-digit’ information which ensures it matches that on the pick sheet or terminal. If their is a match, it is further confirmation they have found the correct location or product and they are able to proceed with the item pick. If it is a failed match, the operative is prevented from completing the pick task, and so knows to look again for the correct storage location.

Check digits are often provided by the warehouse management system, as randomized characters forming an addition to the location code. Most barcodes include a check digit within the symbology, calculated by other characters which form that barcode. In a storage environment, the check digit is typically a separate feature.

Below, you can see the user check digit presented as characters with a black background on a warehouse rack label and a barcode location sign. The operator reads the location reference, scans the barcode and enters the check digit.

We can create one from scratch if needed, there is a cost for this but we keep it low to ensure it is a cost effective alternative.

Why not email with your questions and any data information for us to consider with the response?

We are here to help, call us on (877) 447-9798 and ask the questions to help you progress your project.

Our online store provides customers with the opportunity to purchase standardized products. The same technology, production and quality control methods are used, so you can be assured of their performance and durability.

Browse now