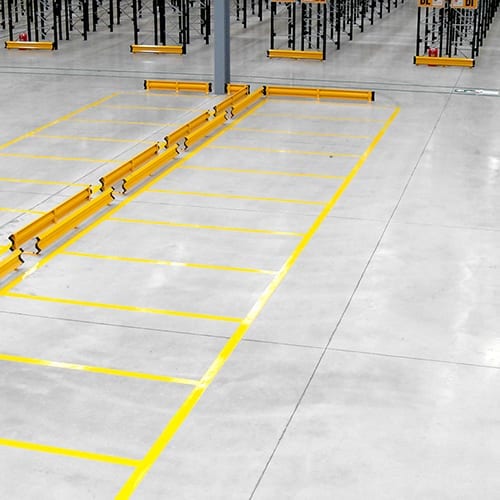

Many consider warehouse floor striping to simply be paint on floors, which technically it is, however those who use floor markings know how difficult it is to find a ‘durable’ method which lasts.

ASG Services provide several methods of warehouse floor striping, each with their own characteristics and prices. The simple fact is, for striping to last, preparation work must be carried out, this unfortunately increases the associated project cost.

ASG Services will talk through your requirements and usage needs which give us a better understanding of your desires. Following this, we can discuss access, budgets and other restrictions and propose accordingly.

Something we place particular emphasis on is concrete preparation. We will be very careful to explain this fully so you can discuss in depth and/or with your building owners. Some are not accepting of certain preparation methods, however we find with the right approach and information, many give the go ahead.

The method of warehouse floor striping chosen will dramatically affect the duration and complexity of an installation, therefore the planning and design process is of extreme importance.

Our project team will work with the customer to create a final layout drawing, depicting the walkways, storage lanes, numbering and other floor marking designs. The importance of this is to provide a map which can be broken into segments showing how much can be installed per day.

Once this is established, the customer can arrange access, agree areas and allow ASG Services to begin preparations. This will also therefore provide the governance for the warehouse floor striping installation, however we understand that the unforeseen must be dealt with, we would approach this with maximum flexibility.

The schedule map will also show when areas are due to become available, helping customers minimize downtime in storage areas and freeing up valuable space.

Floor marking projects often require considerable access and downtime for areas being worked. This means restrictions and the loss of valuable floor space for the customer’s operation.

Our installation teams operate under the guidance of the projects department, however they also maintain maximum flexibility and executive decision making. This is because, during the installation of warehouse floor striping, an installation team may be presented with extreme difficulties, with the substrate, coating systems, equipment and of course their customer’s operational requirements. This means they have to think and react quickly, making a decision and committing to it.

Any changes which happen along the way are reported to the projects department who evaluate and update the schedule accordingly. This is imperative when dealing with a 7,000 Lin/ft or 70,000 Lin/ft project. Both would be affected widely by the increase in cost percentage associated.

Our installation teams are fully trained and insured to work on all customer sites, not to mentioned, they are the same people who work in Florida, California, New York, Washington, etc. Our teams travel, simply because our teams are the best and our customers expect the best.

Preparation helps improve durability, so if you are operating a very busy facility or moving items which are heavy, you will likely need a preparation method.

There are several options to consider:

It is typically more cost effective to have a preparation method when compared to several years of recoating and touch ups which will be needed.

OSHA recommends the following:

Most work carried out by ASG Services is done with yellow and/or white. Occasionally we will be asked to use red, green, blue and grey. If in doubt ask what we can provide, almost any color is available.

For the most accurate price and planning, it is best to give us as much as possible, having a drawing helps you visualize and us to plan and quote. CAD are easiest as we can use them to pull measurements from, while PDF with measurements added is another great way to provide us with the information.

However this is not essential, we can help with basic depictions or arrange for a partner firm to visit site and create a much more detailed drawing, contact us for pricing.

Our teams are able to forecast, with a good level of accuracy, installation times of all products we produce and the floor markings we create. Many factors come into the calculation as you might expect, so a detailed discussion will be needed to develop the time frame. It will be this framework we use for our project planning.

Line widths are not critical, but there are several considerations to make, some are as follows:

Other considerations:

Please feel free to call us on (877) 447-9798, we're here to help you complete the project and have the best solutions available.

Emailing enables you to ask the questions, show us pictures and pass drawings to us, so our response is as complete as possible.

Durable Striping

Durable Striping

The premium warehouse striping solution is ASG Services world renowned embedded striping.

Floor Coatings

Floor Coatings

Throughout the warehouse and distribution industry, ASG Services have provided floor coatings for new and existing facilities.

Epoxy Floor Striping

Epoxy Floor Striping

Unprepared floor striping is a term given to epoxy paint which is applied to the floor without any concrete preparation taking place.

External Striping

External Striping

Line striping for trailer parking lots in distribution center yard areas improve space management and safety in your workplace, we help you achieve the two with external and internal installations.

Floor Tape

Floor Tape

Adhesive floor striping tape is easy to install, clean to use and can be applied quickly if needed. ASG Services provide several options to suit durability and budget needs.

Our online store provides customers with the opportunity to purchase standardized products. The same technology, production and quality control methods are used, so you can be assured of their performance and durability.

Browse now